PP-HOMOPOLYMER

Polypropylene is in many aspects similar to polyethylene, especially in solution behavior and electrical properties. The additionally present methyl group improves mechanical properties and thermal resistance, while the chemical resistance decreases. The properties of polypropylene depend on the molecular weight and molecular weight distribution, crystallinity, type and proportion of comonomer (if used) and the isotacticity . Polypropylene is at room temperature resistant to fats and almost all organic solvents, apart from strong oxidants. Non-oxidizing acids and bases can be stored in containers made of PP. At elevated temperature, PP can be solved in of low polarity solvents (e.g. xylene, tetralin and decalin). Due to the tertiary carbon atom PP is chemically less resistant than PE.

As polypropylene is resistant to fatigue, most plastic living hinges, such as those on flip-top bottles, are made from this material. However, it is important to ensure that chain molecules are oriented across the hinge to maximize strength. Very thin sheets (~2–20 µm) of polypropylene are used as a dielectric within certain high-performance pulse and low-loss RF capacitors. Polypropylene is used in the manufacturing piping systems; both ones concerned with high-purity and ones designed for strength and rigidity (e.g. those intended for use in potable plumbing, hydronic heating and cooling, and reclaimed water).

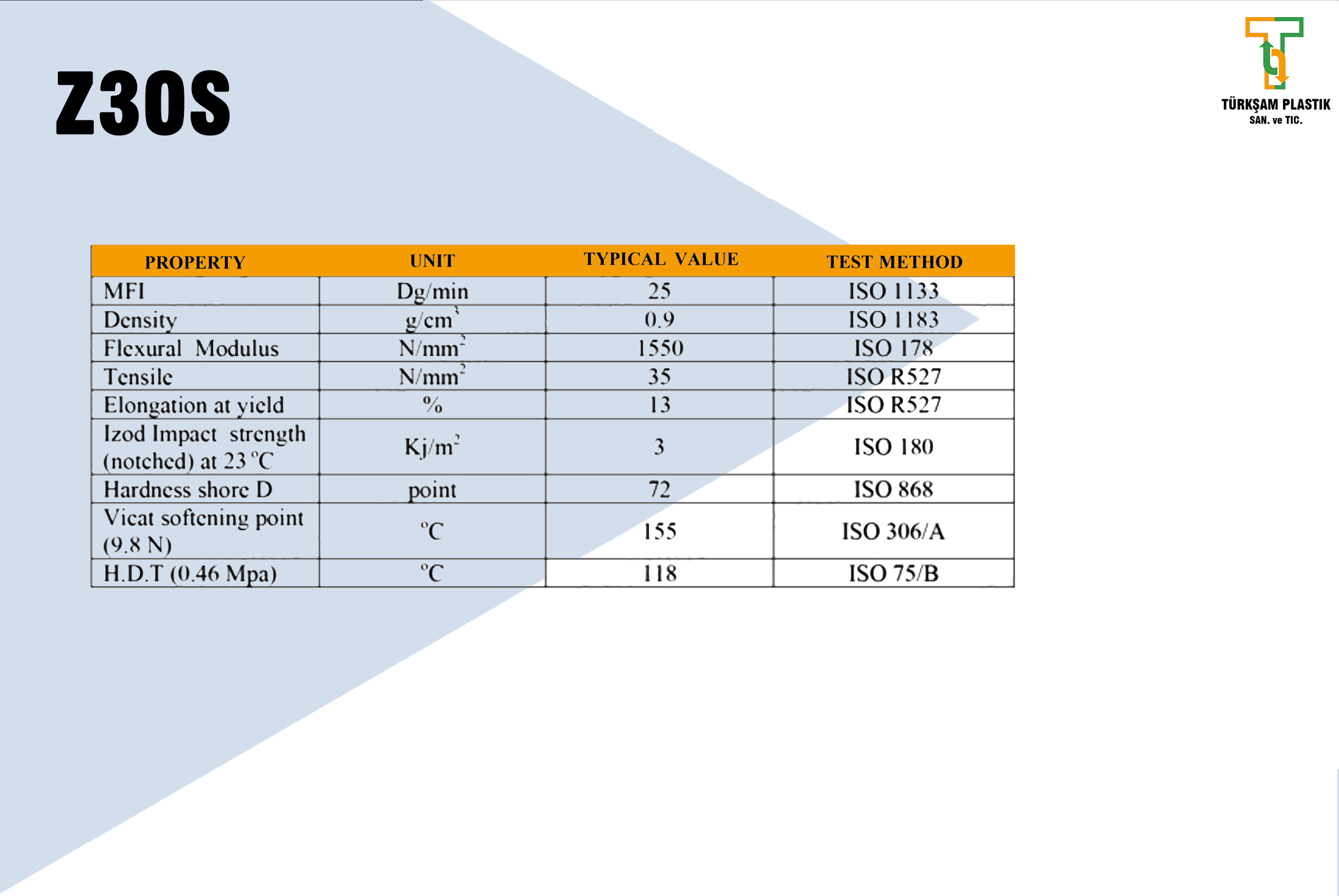

Z30S

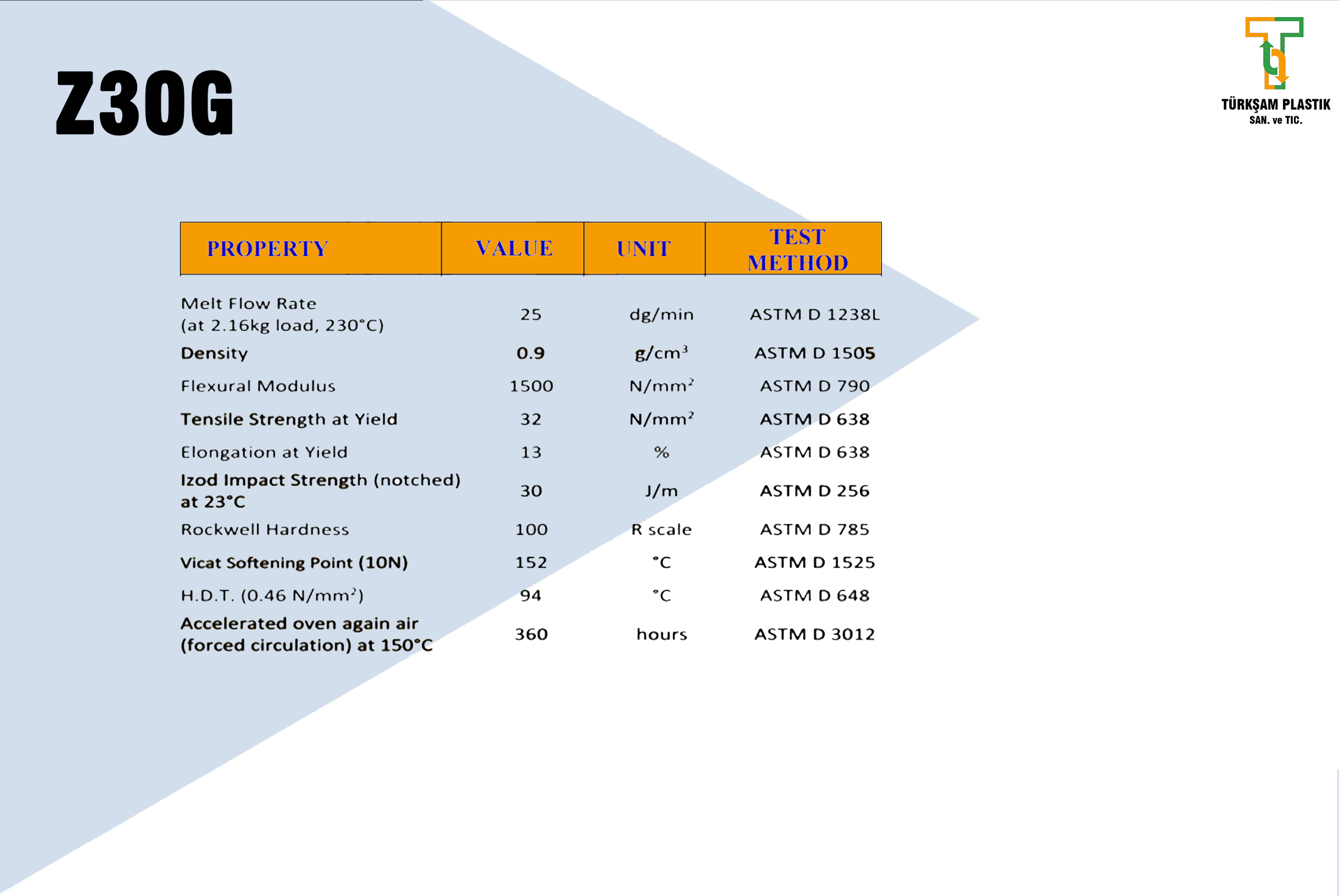

Z30G

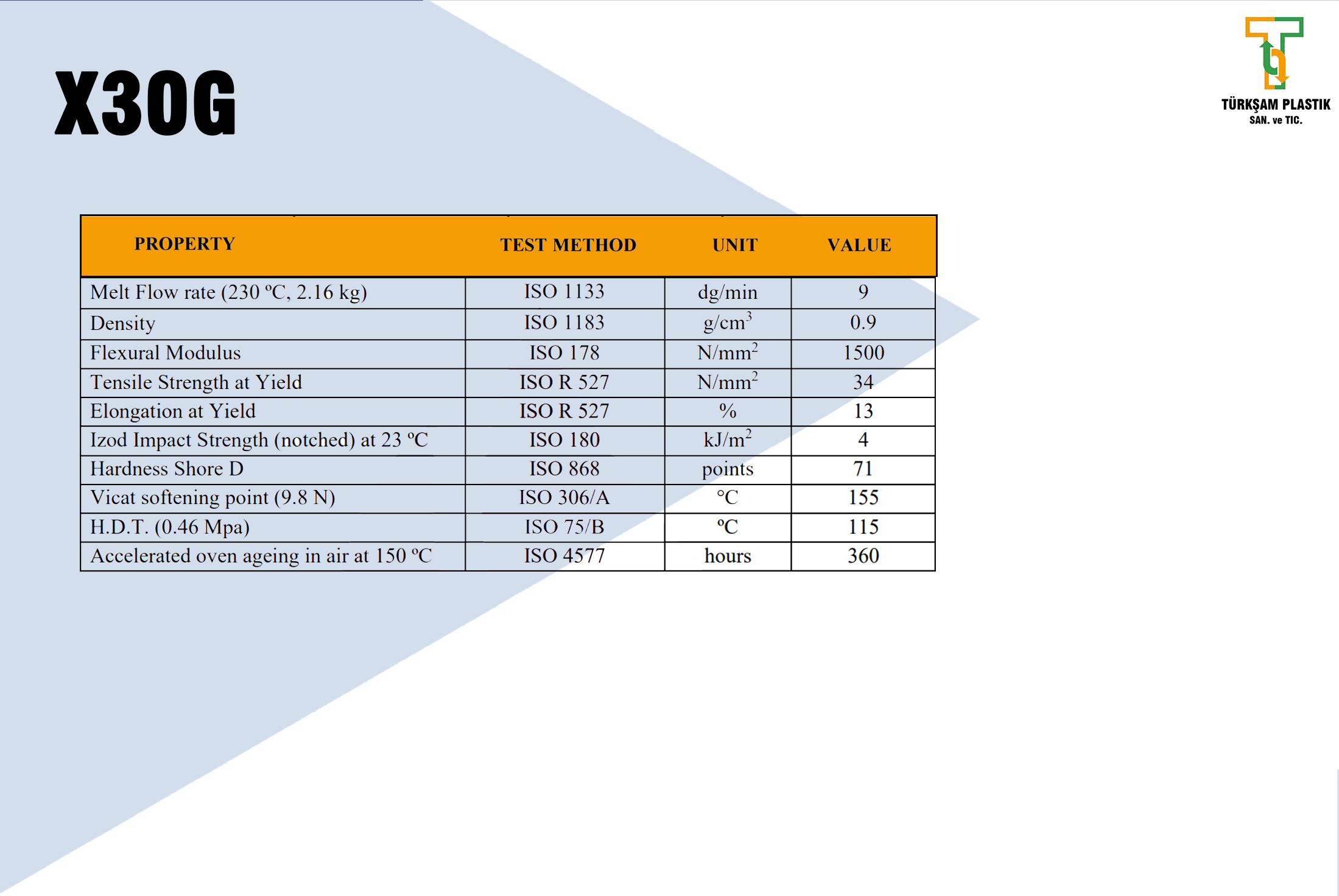

X30G

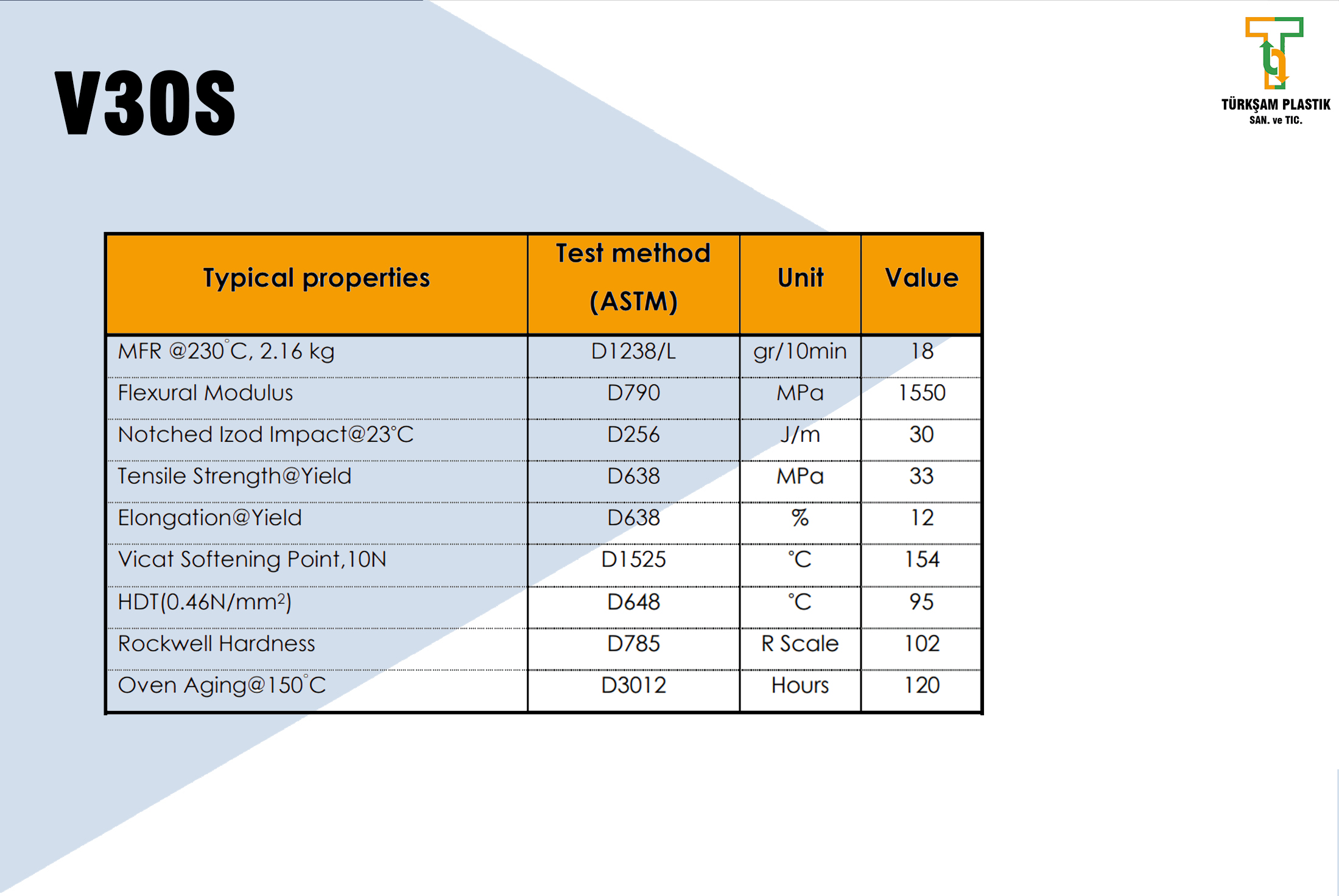

V30S

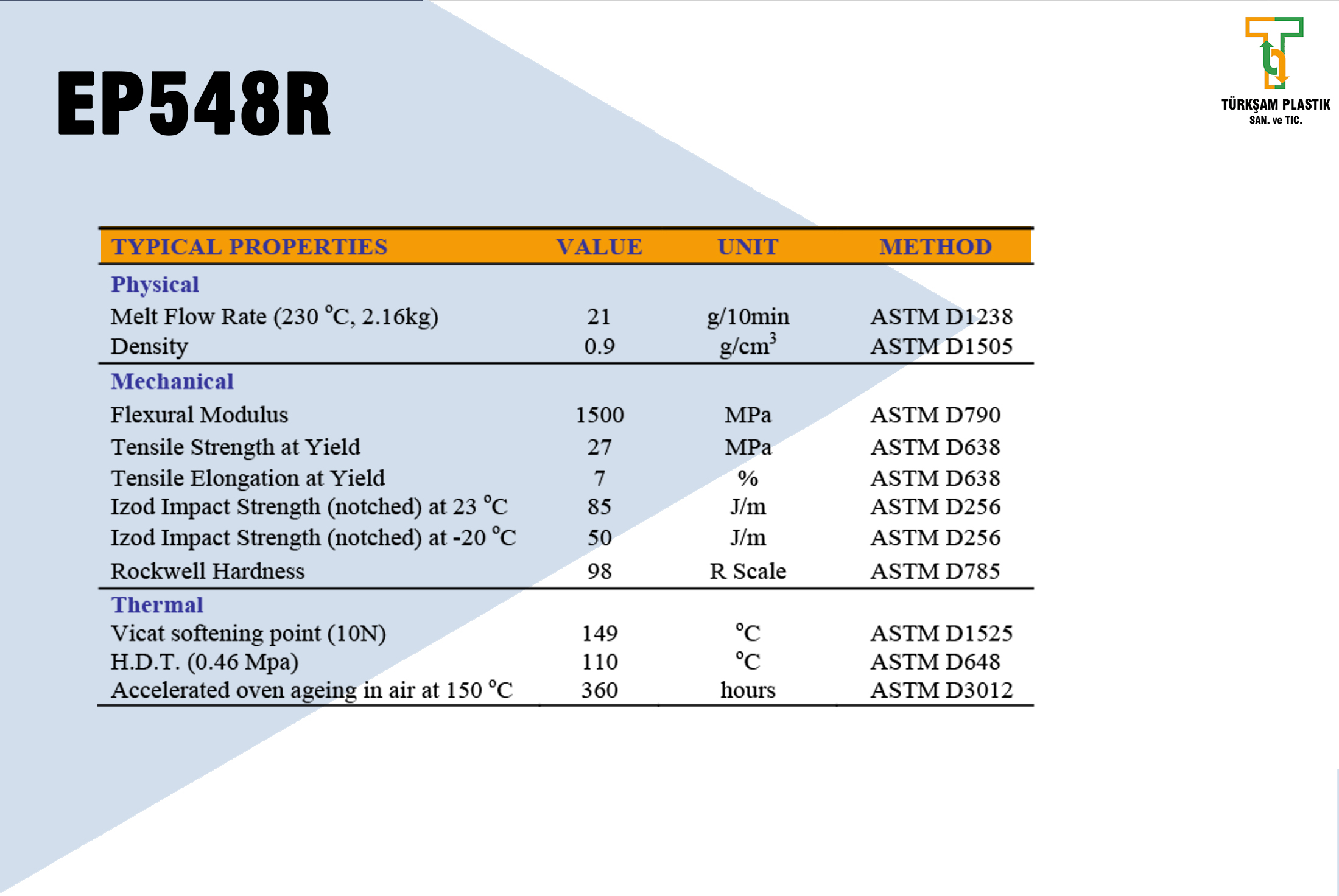

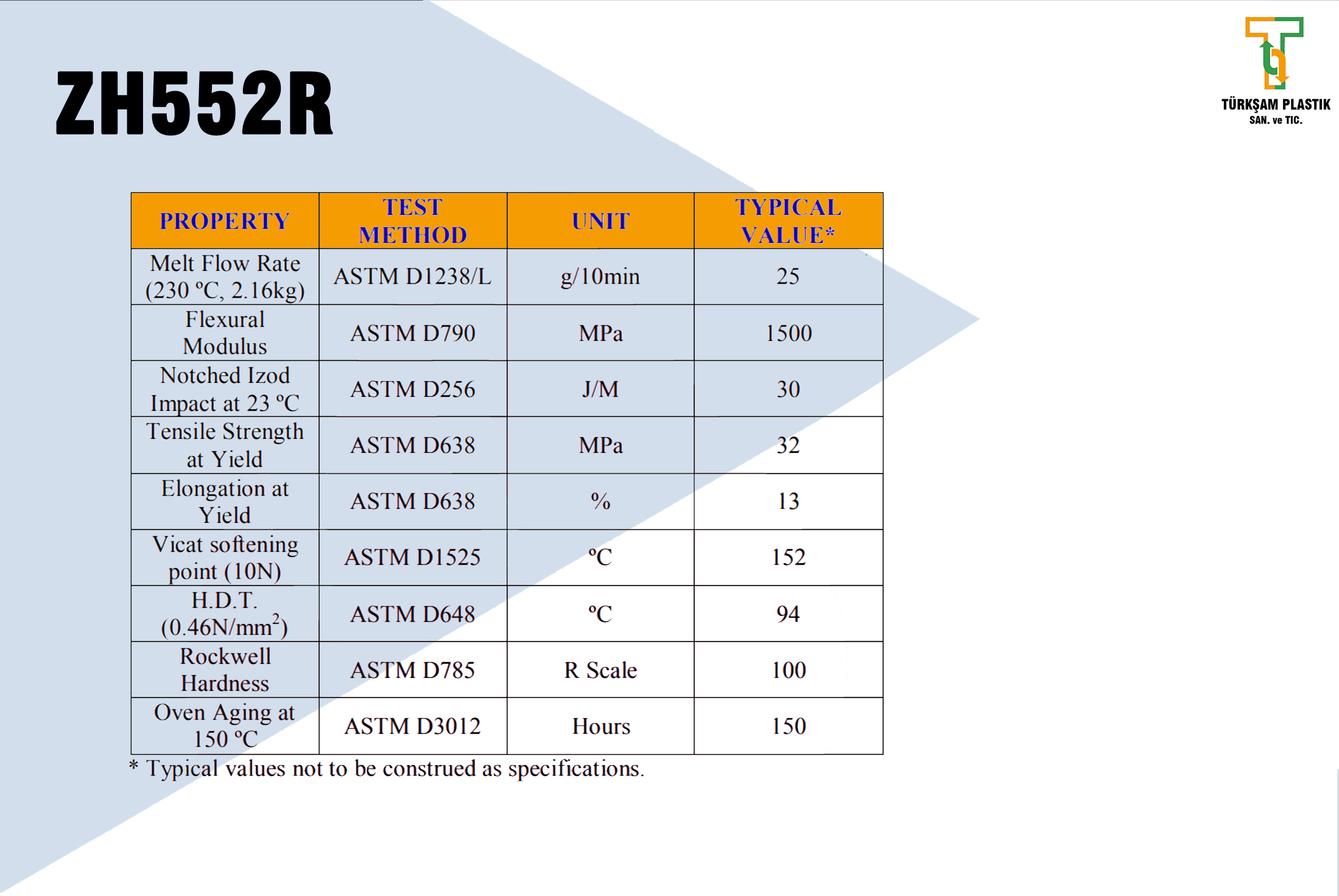

552R

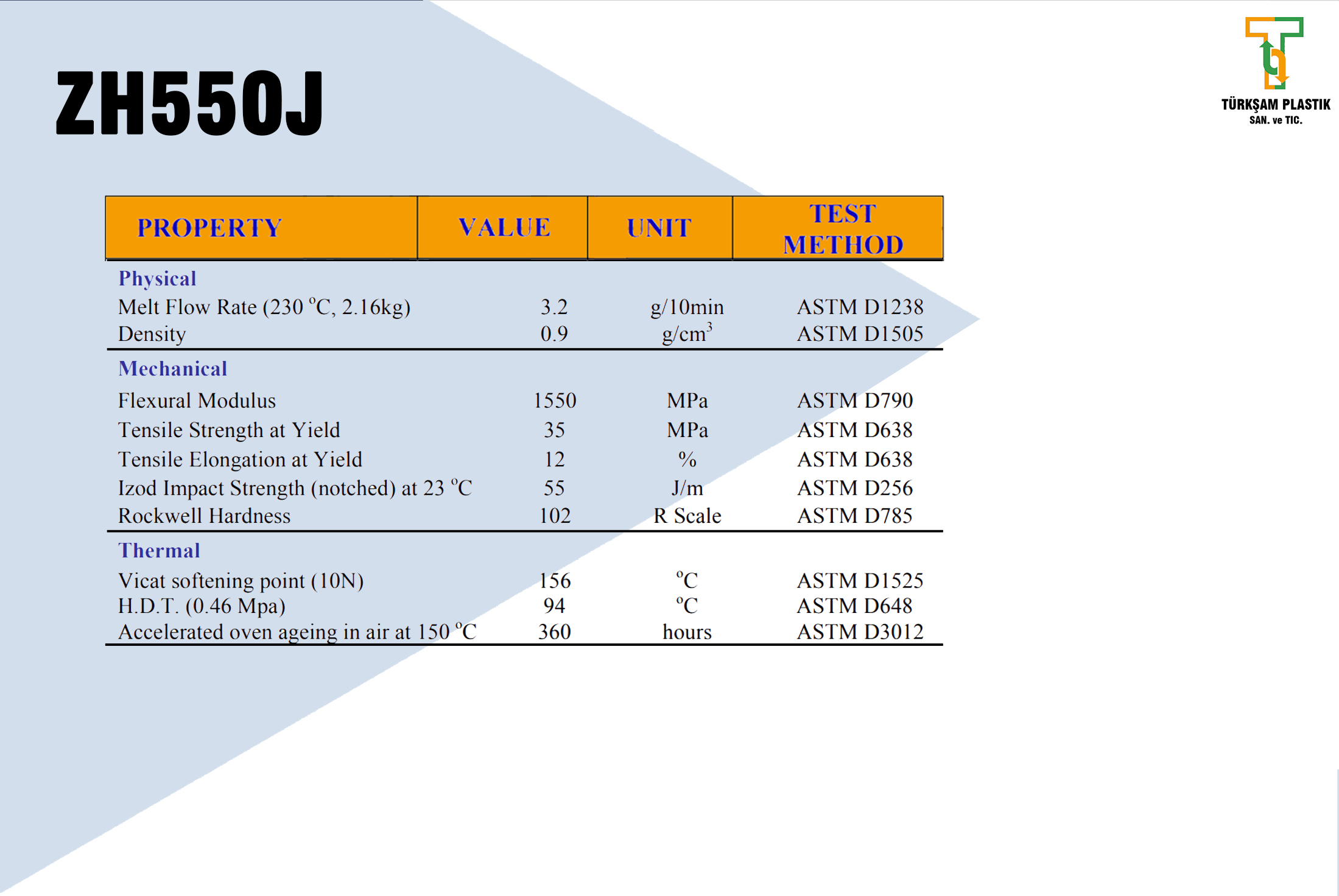

ZH550J

PP-COPOLYMER

Polypropylene copolymer (PPC) is a bit softer but have better impact strength, is tougher and more durable than homopolymer polypropylene. Copolymer polypropylene tends to have better stress crack resistance and low temperature toughness than homopolymer at the expense of quite small reductions in other properties.

A large number of end use applications for PP are possible by tailoring grades with specific molecular properties and additives during its manufacture.

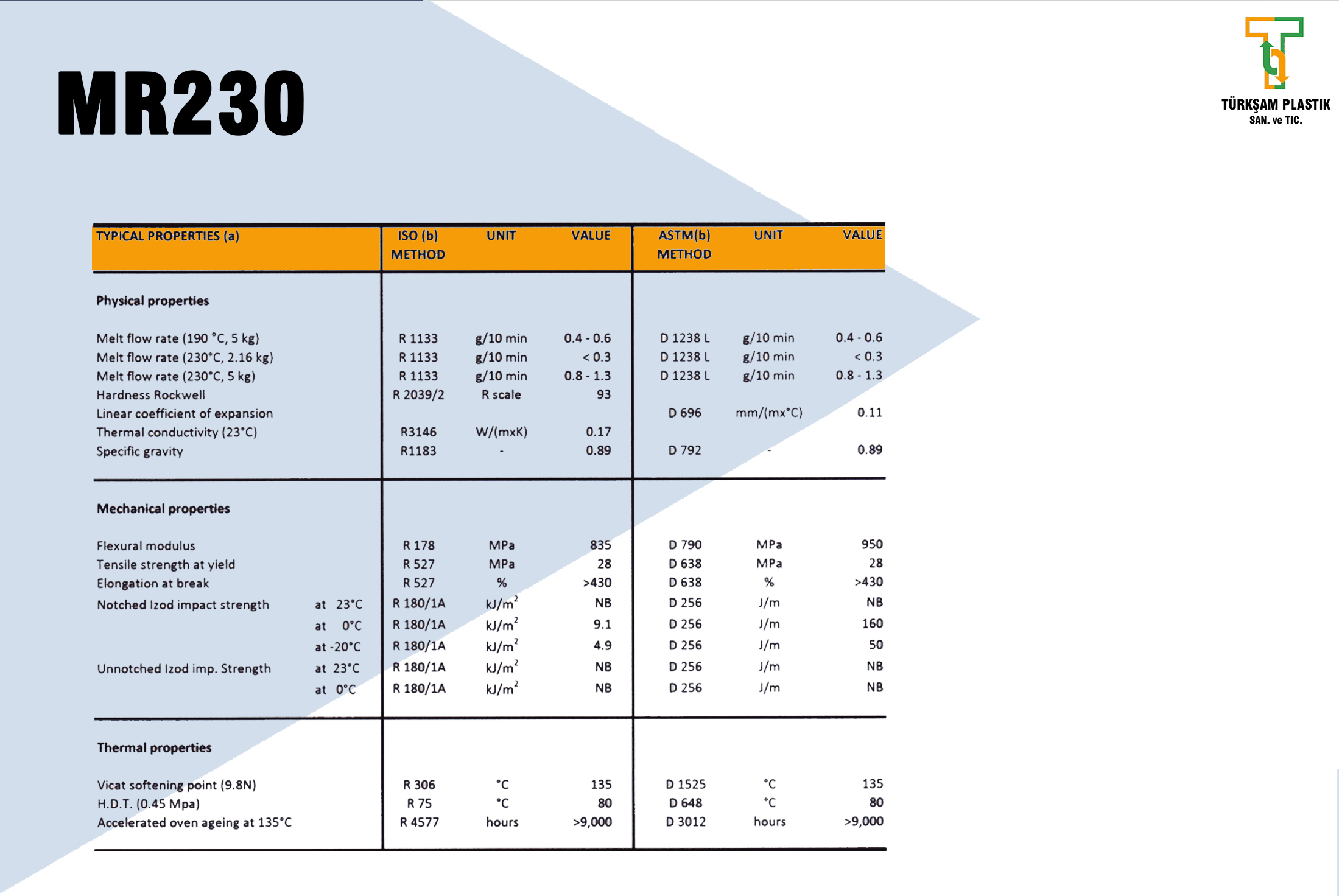

MR230

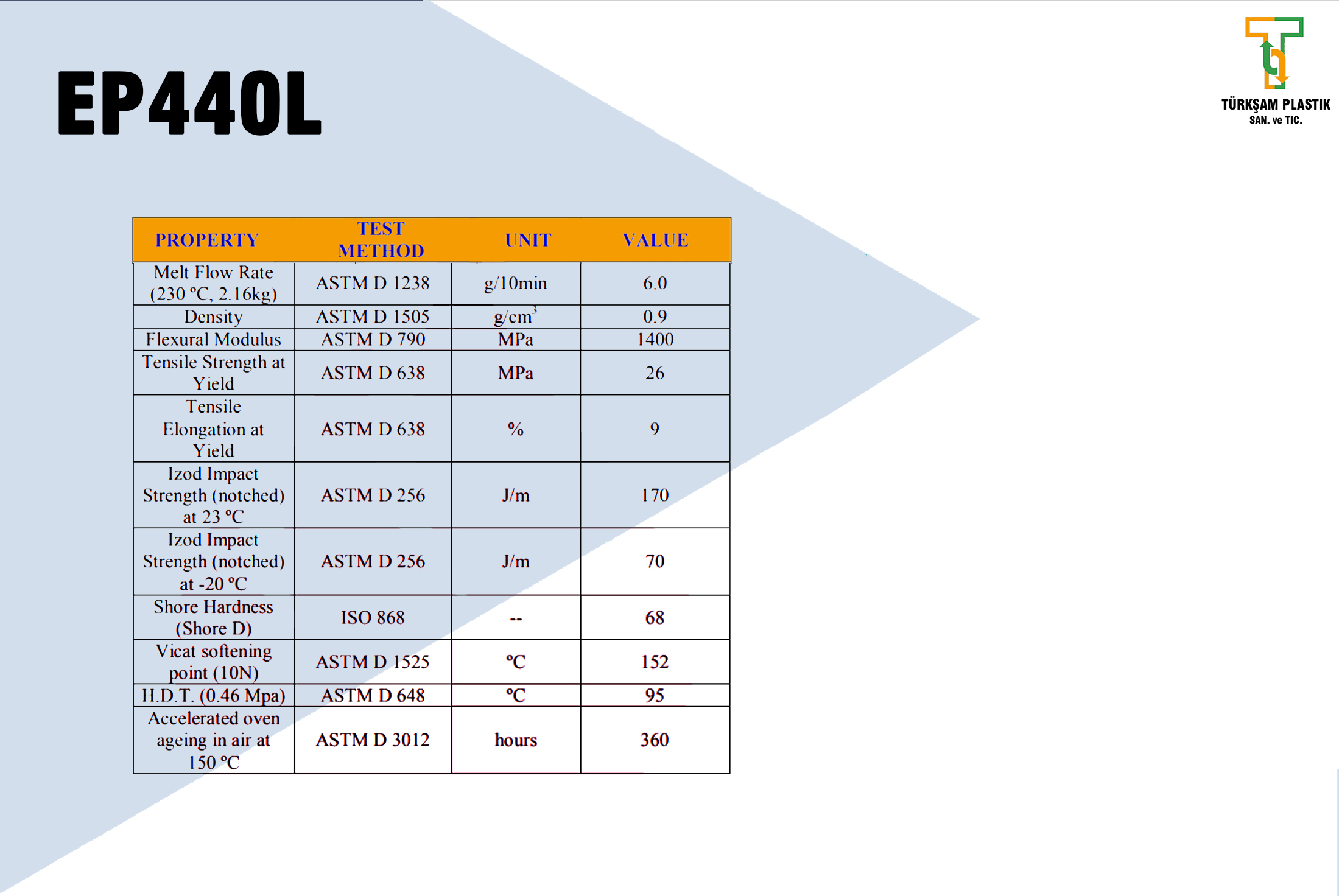

EP440L

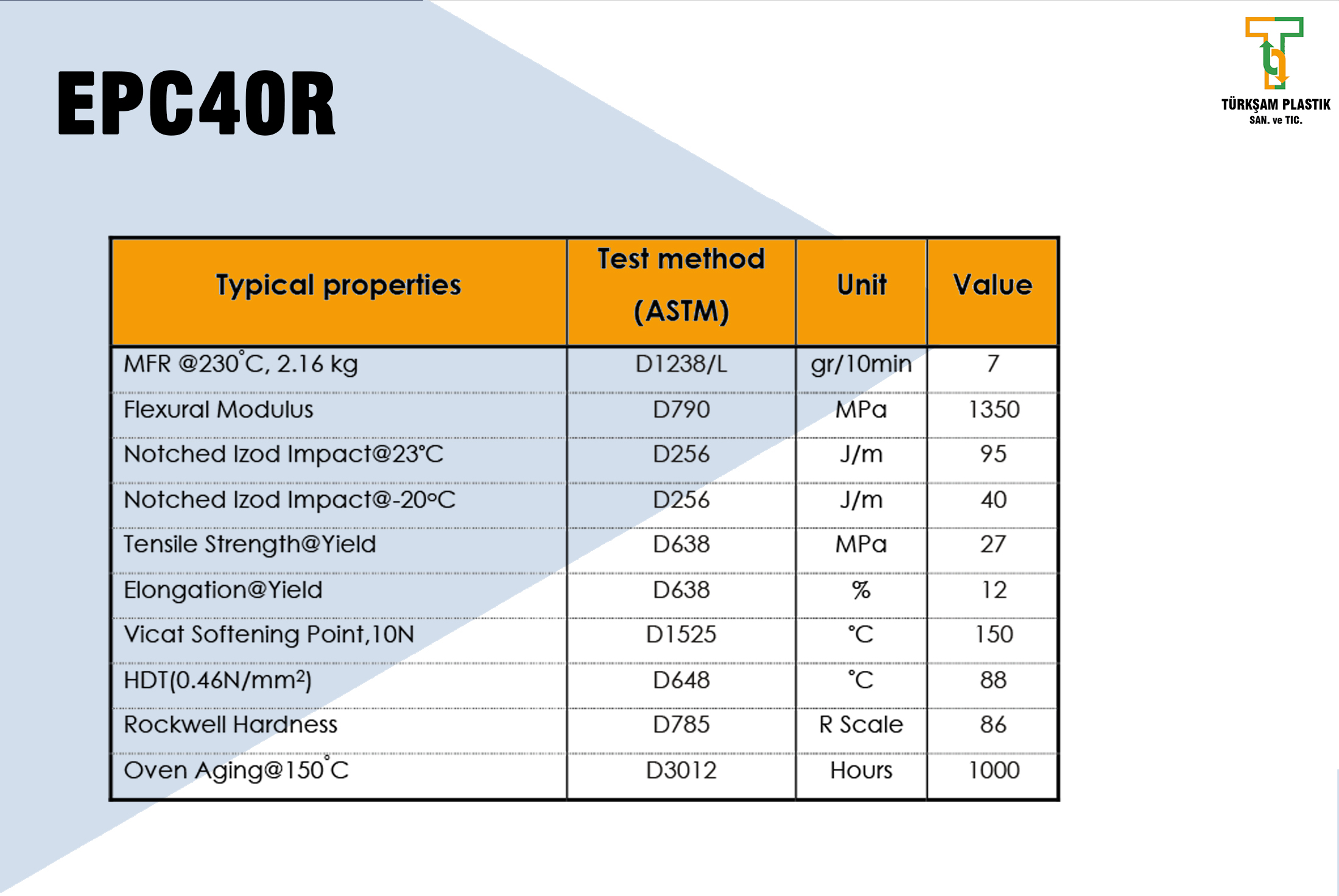

EPC40R