LDPE

POLYETHYLENE (LDPE)

LDPE is defined by a density range of 0.910–0.940 g/cm3. It is not reactive at room temperatures, except by strong oxidizing agents, and some solvents cause swelling. It can withstand temperatures of 80 °C continuously and 95 °C for a short time. Made in translucent or opaque variations, it is quite flexible and tough. LDPE has more branching (on about 2% of the carbon atoms) than HDPE, so its intermolecular forces (instantaneous-dipole induced-dipole attraction) are weaker, its tensile strength is lower, and its resilience is higher. Also, because its molecules are less tightly packed and less crystalline due to the side branches, its density is lower.

LDPE is widely used for manufacturing various containers, dispensing bottles, wash bottles, tubing, plastic bags for computer components, and various molded laboratory equipment. Its most common use is in plastic bags.

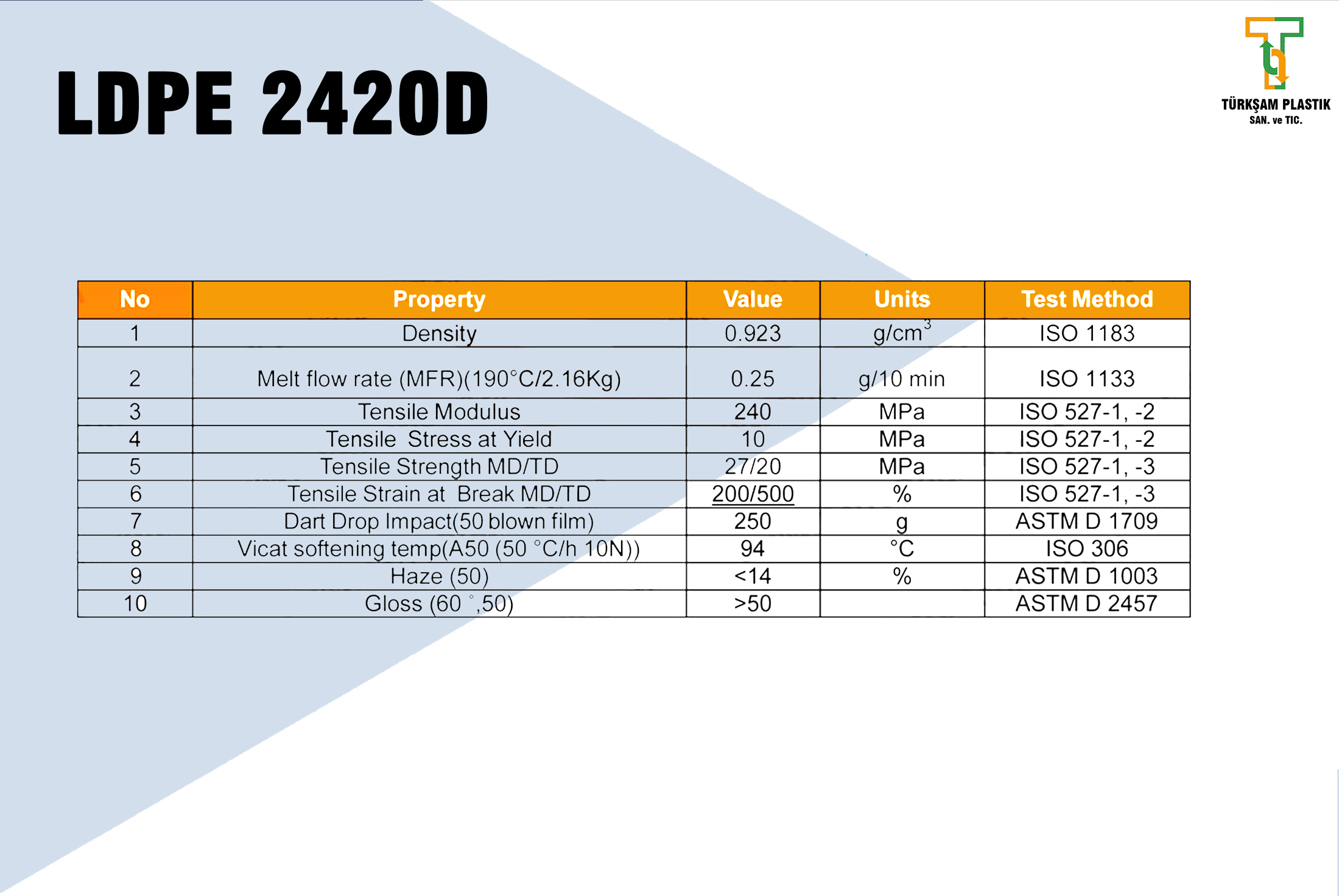

LDPE 2420D

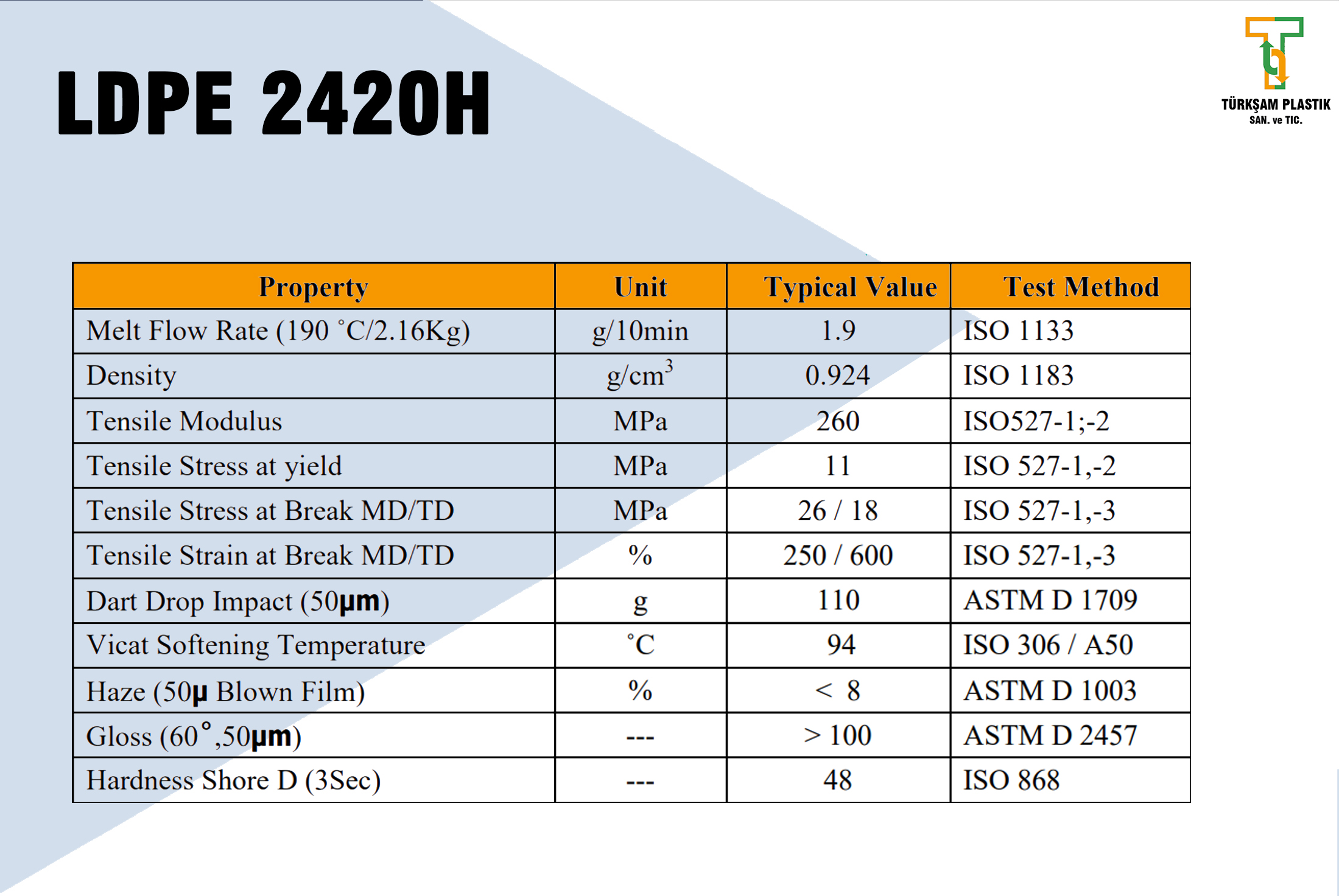

LDPE 2420 H

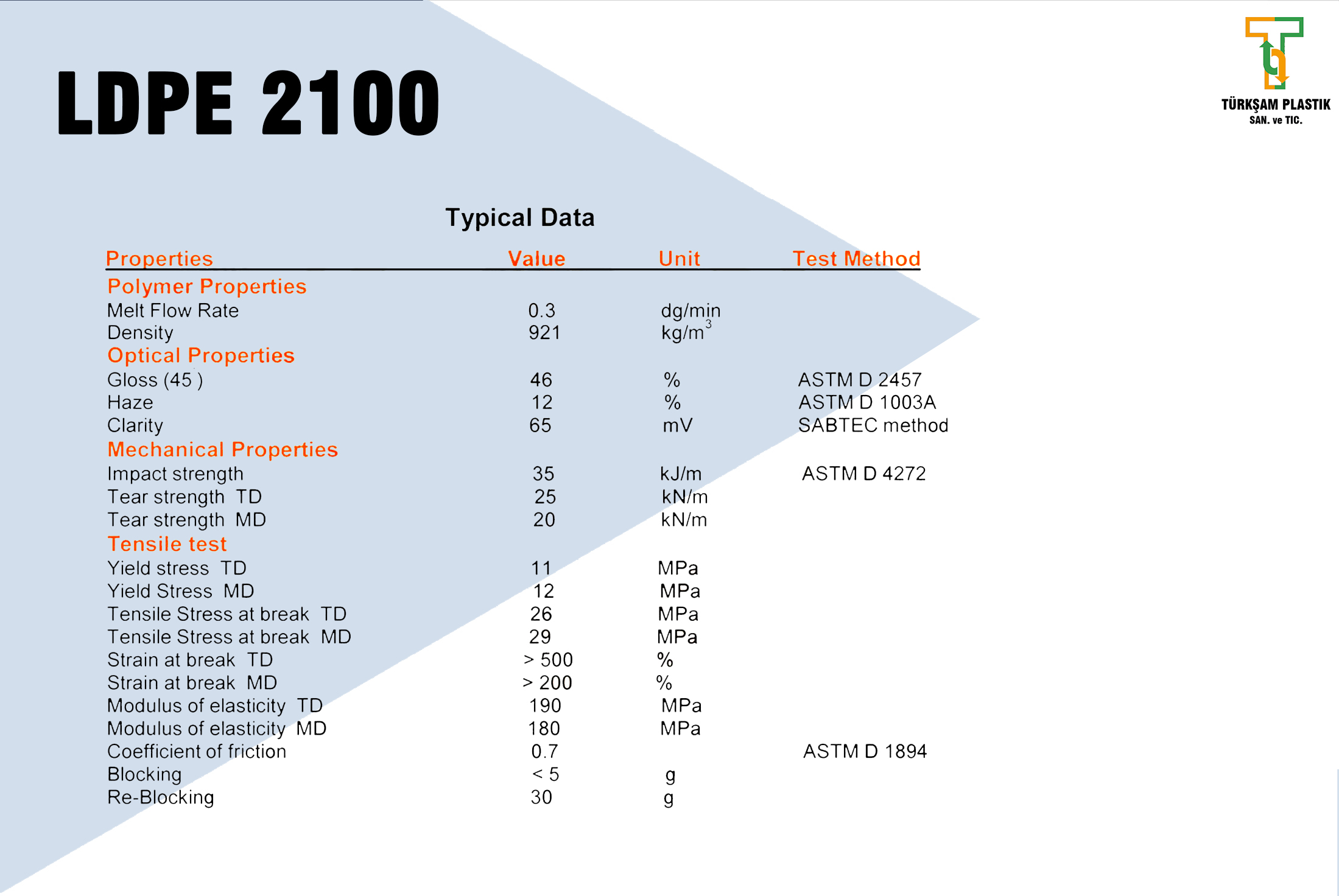

LDPE 2100

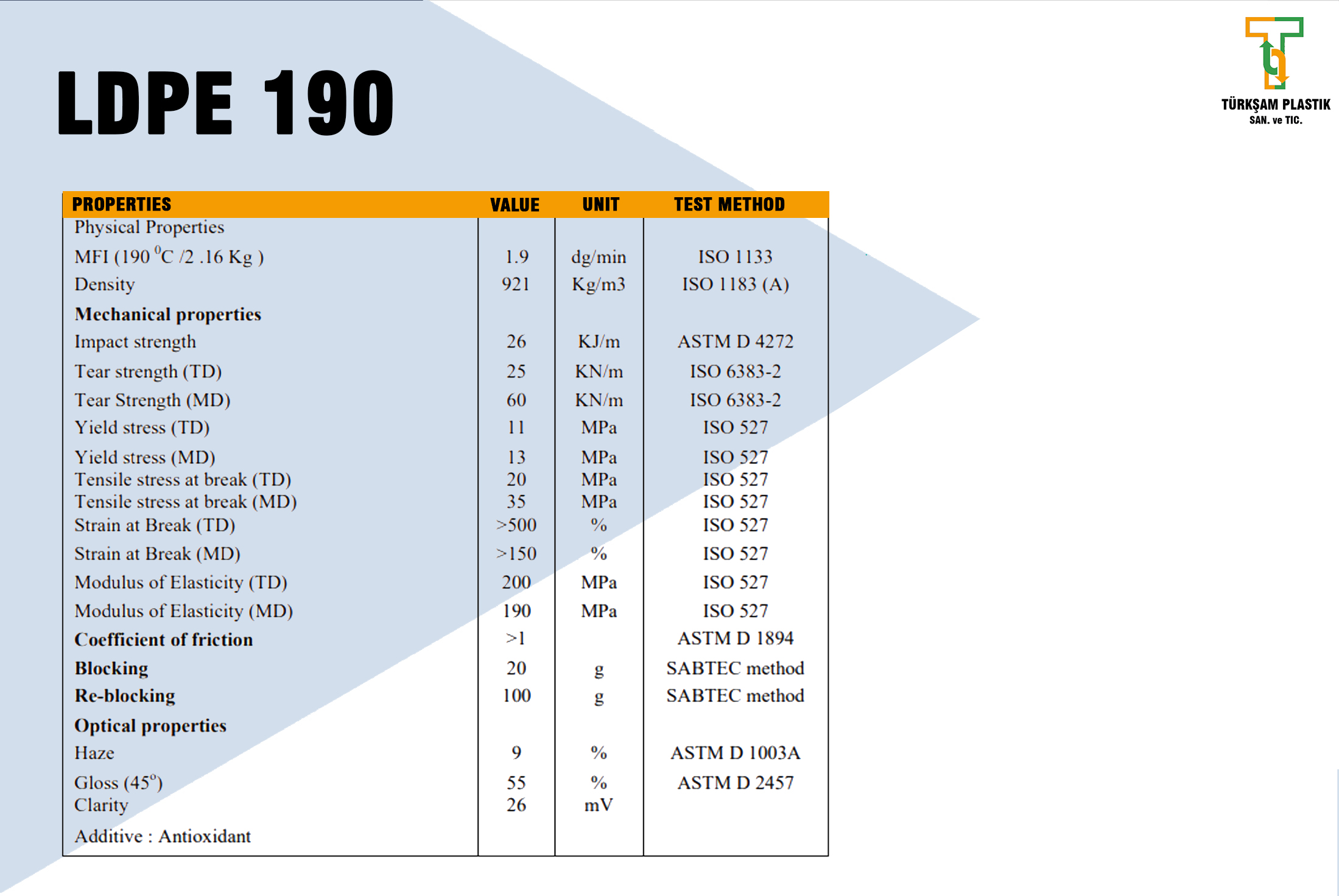

LDPE 190

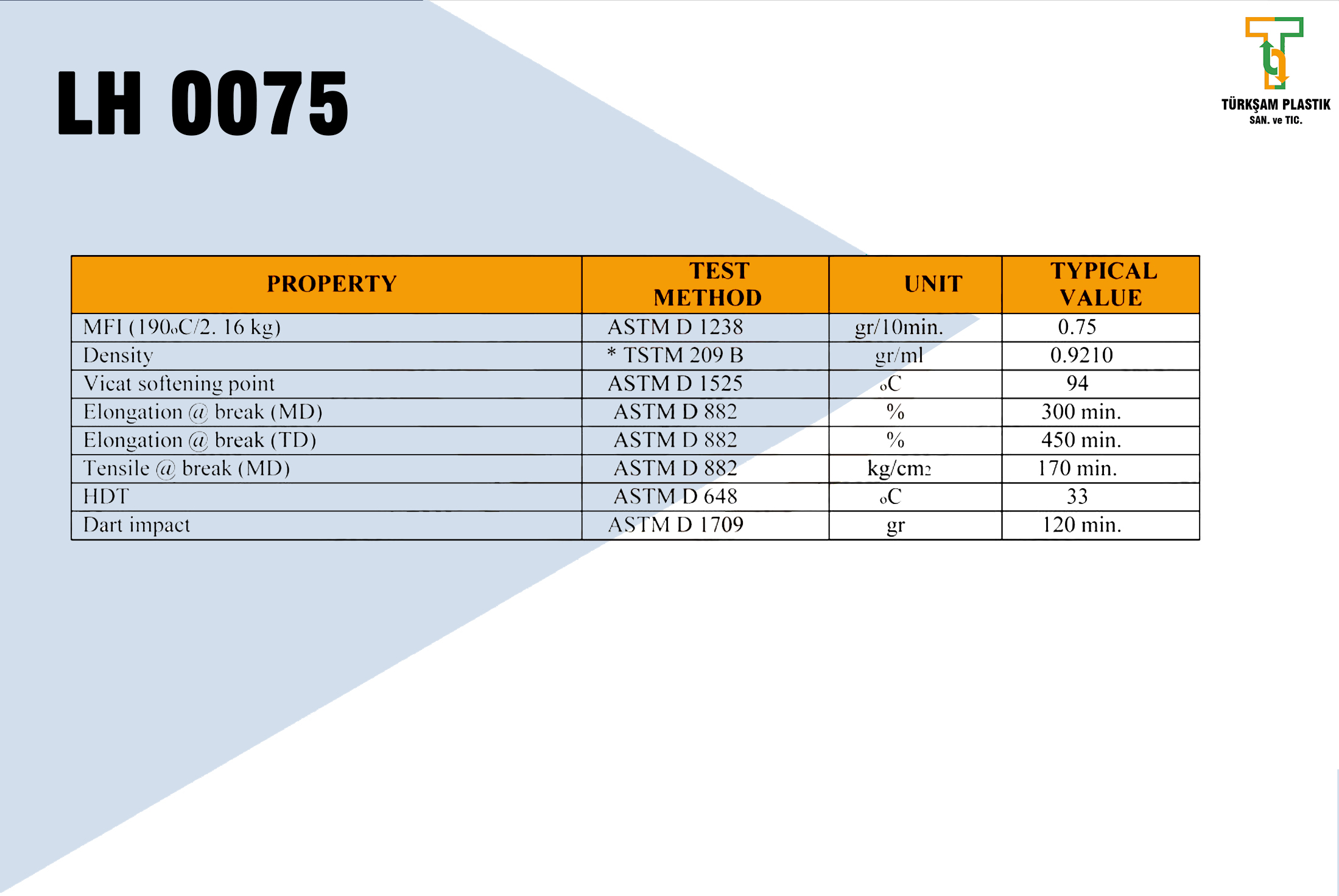

LH 0075

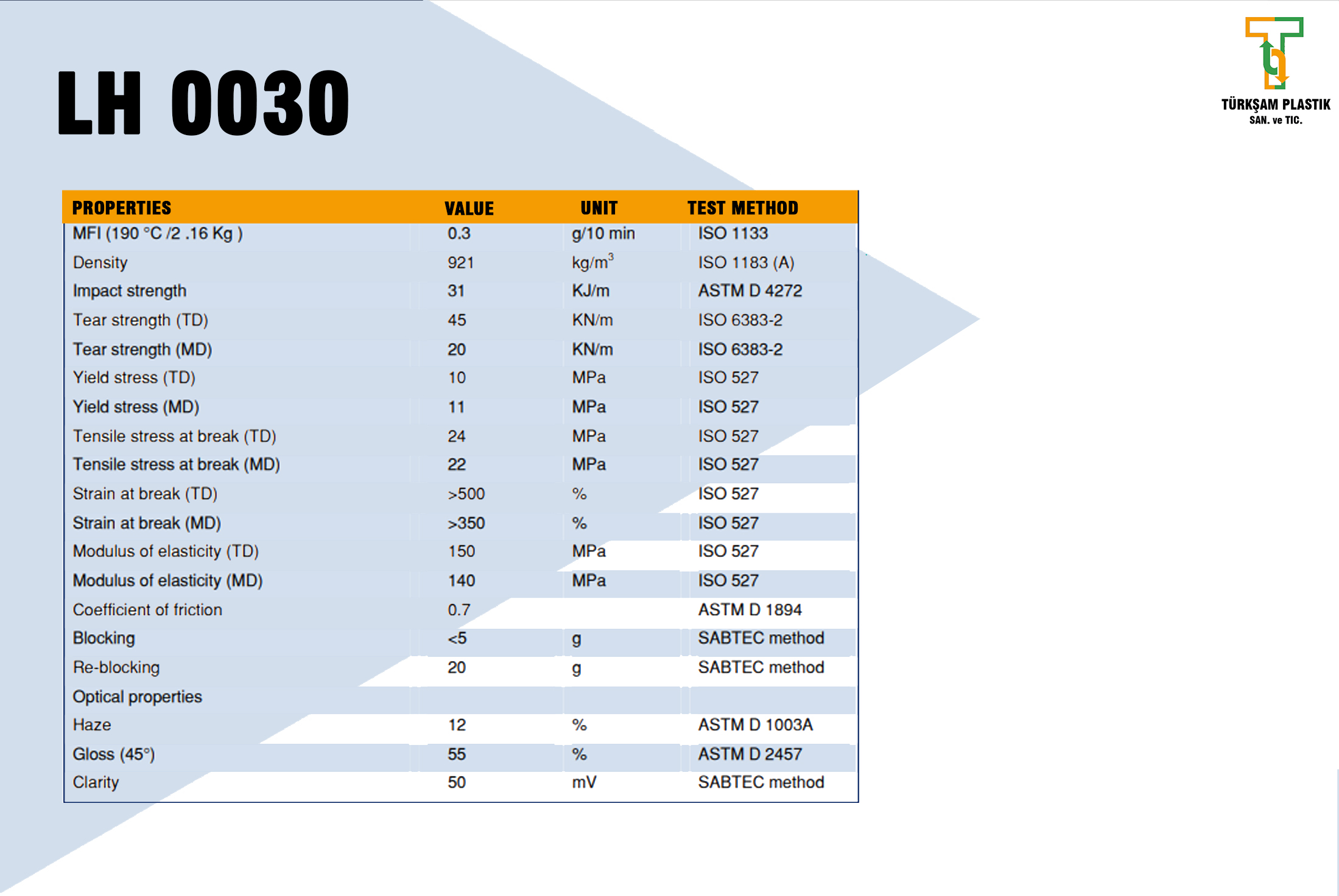

LH 0030

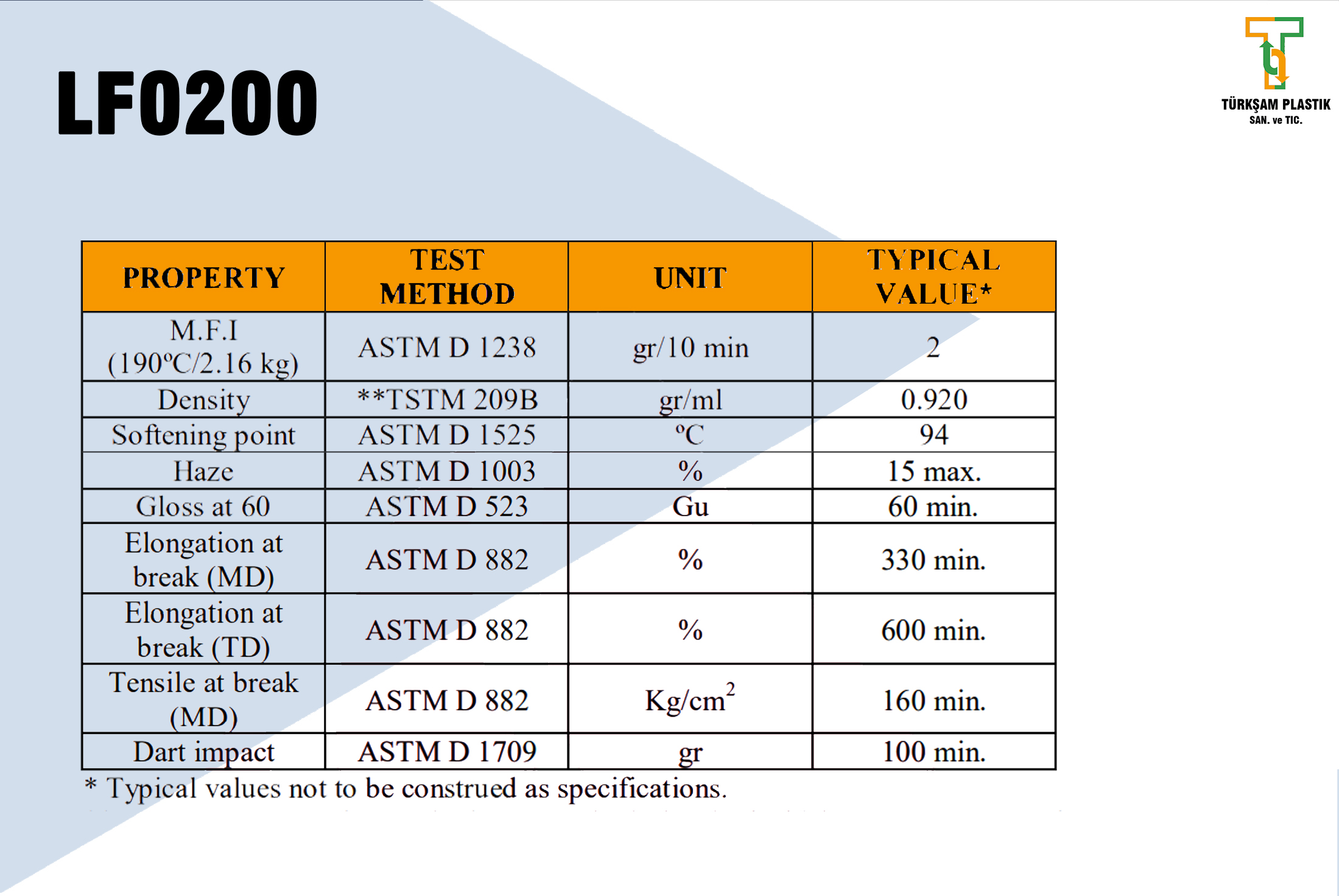

LF 0200

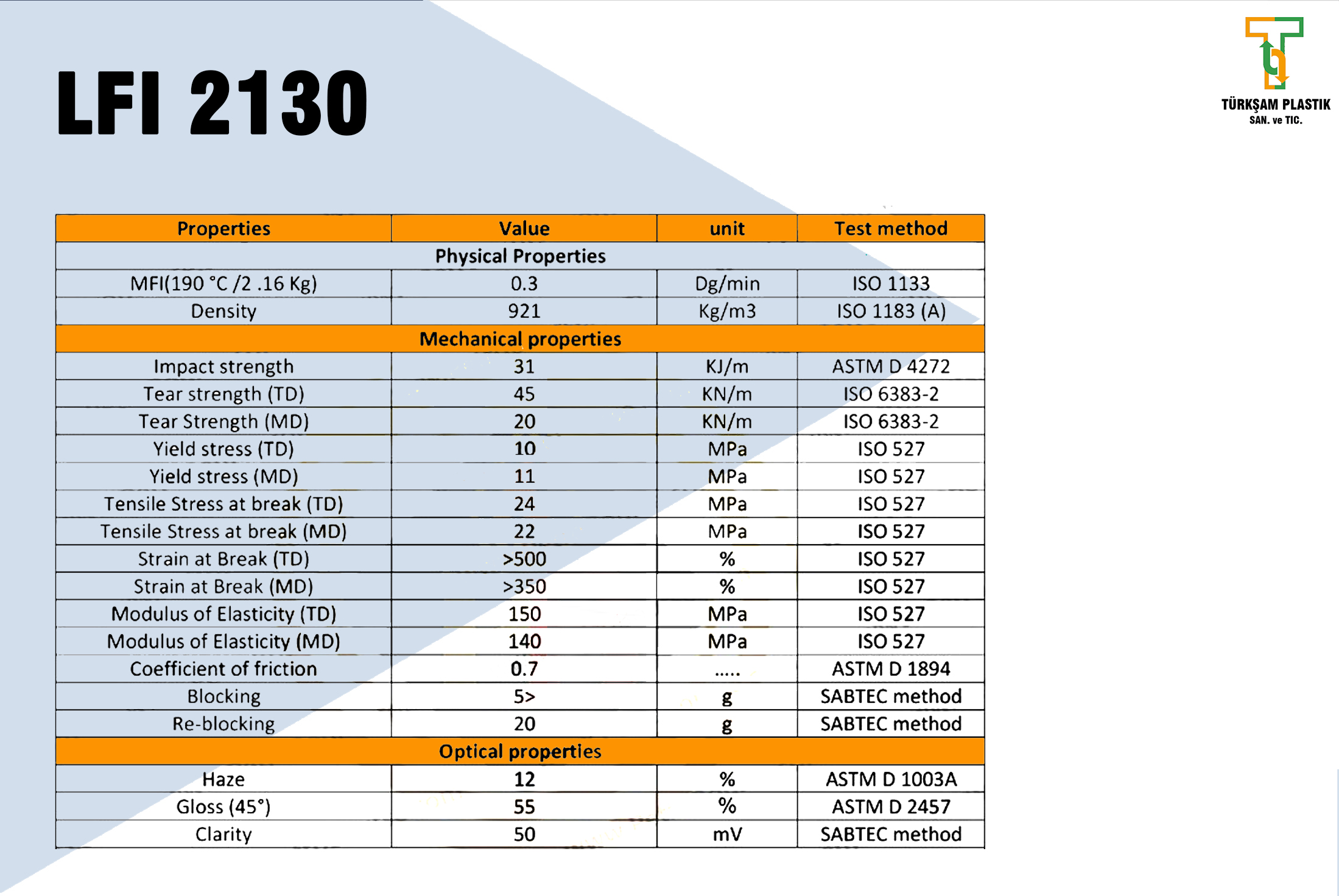

LFI 2130

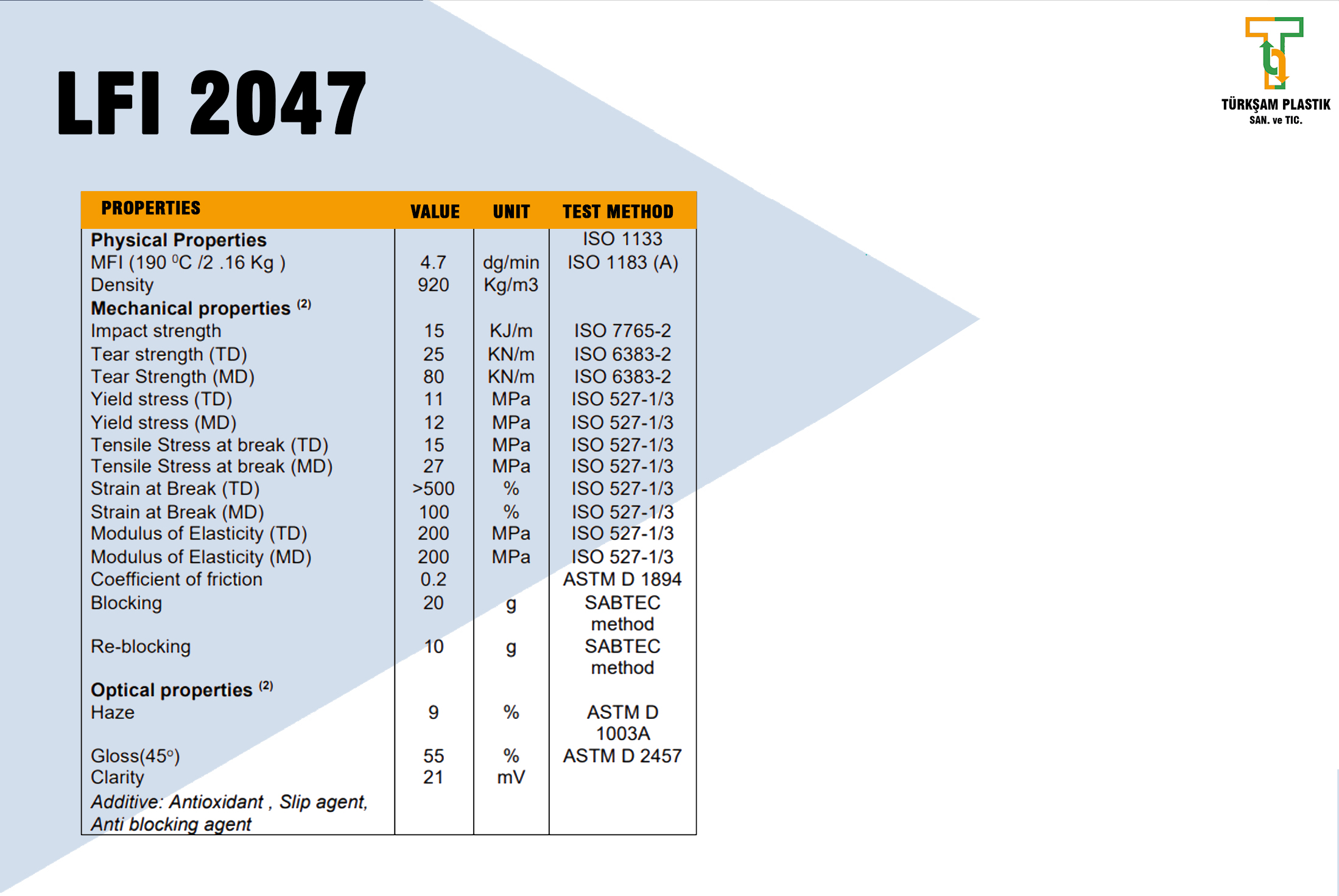

LFI 2047

HDPE

HDPE is known for its large strength-to-density ratio. The density of HDPE can range from 0.93 to 0.97 g/cm3 or 970 kg/m3. Although the density of HDPE is only marginally higher than that of low-density polyethylene, HDPE has little branching, giving it stronger intermolecular forces and tensile strength than LDPE. The difference in strength exceeds the difference in density, giving HDPE a higher specific strength. It is also harder and more opaque and can withstand somewhat higher temperatures (120 °C/ 248 °F for short periods, 110 °C /230 °F continuously). High-density polyethylene, unlike polypropylene, cannot withstand normally required autoclaving conditions. The lack of branching is ensured by an appropriate choice of catalyst (e.g., Ziegler-Natta catalysts) and reaction conditions.

HDPE is resistant to many different solvents and has a wide variety of applications:

Swimming pool/ installation3-D printer filament/Arena Board (puck board)/Backpacking frames/Ballistic plates/Banners/Bottle caps/Chemical-resistant piping/Coax cable inner insulator/Food storage containers/Fuel tanks for vehicles/Corrosion protection for steel pipelines/Personal Hovercraft; albeit too heavy for good performance/Electrical and plumbing boxes

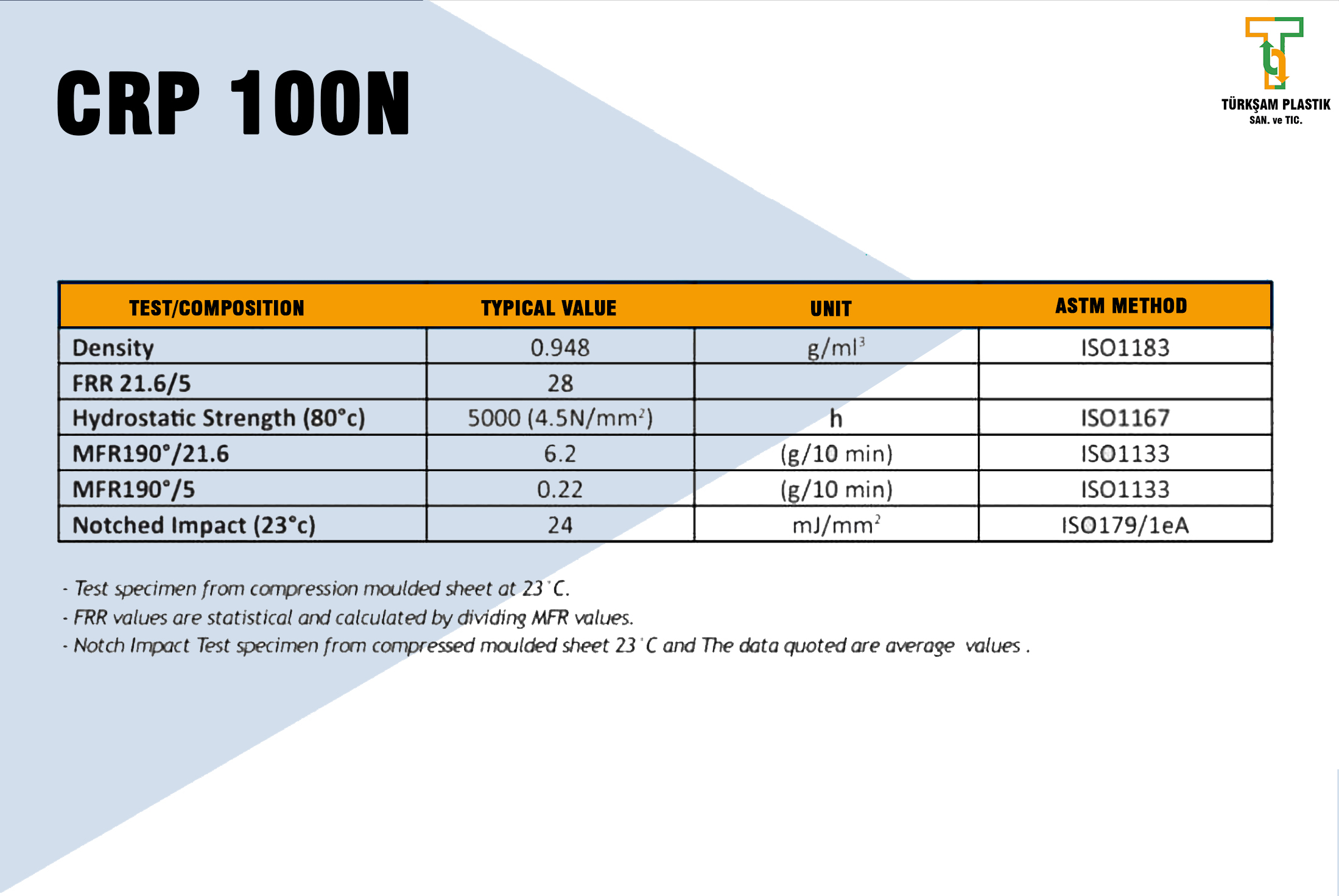

CRP 100N (PE100)

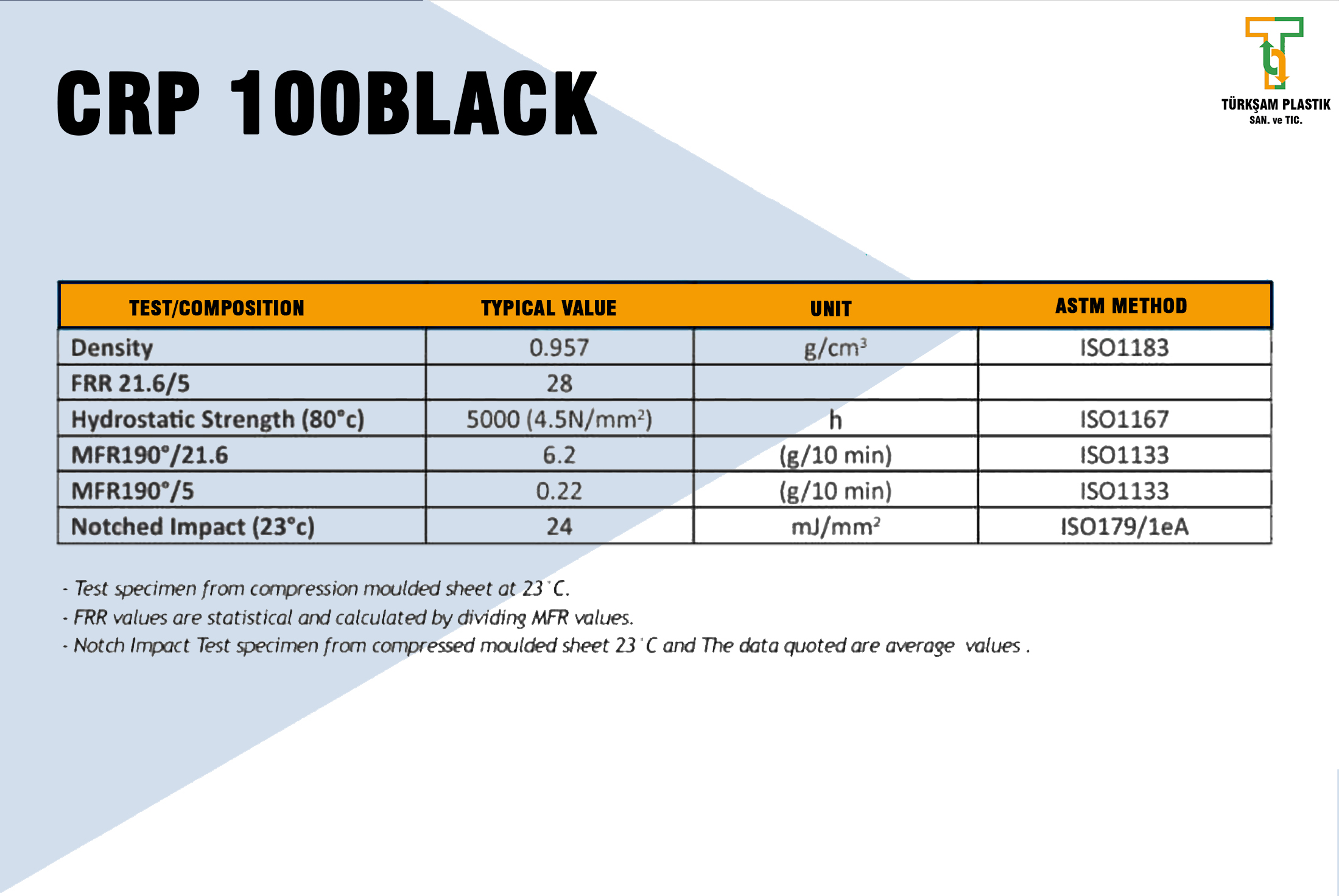

CRP 100 Black (PE100)

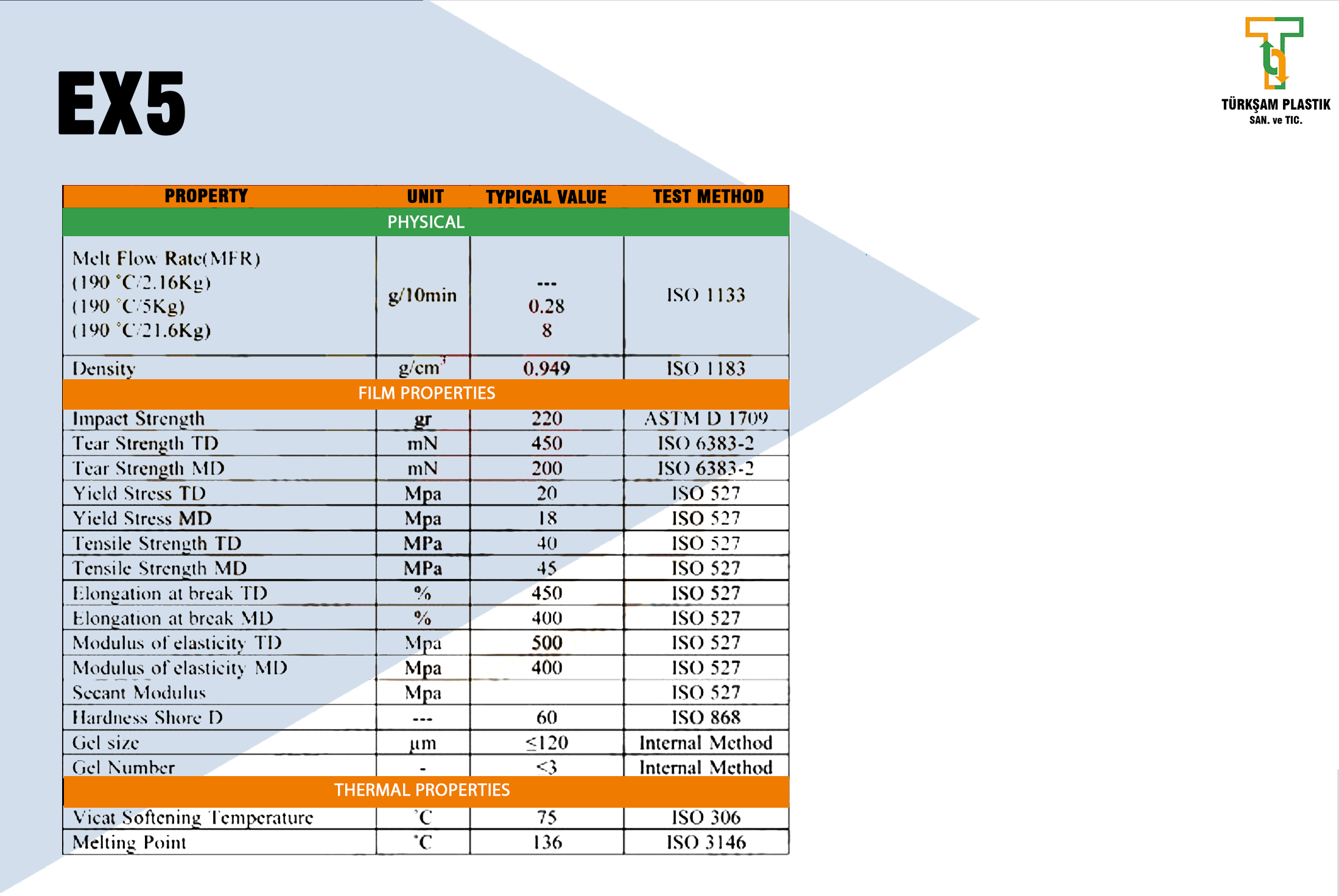

EX5

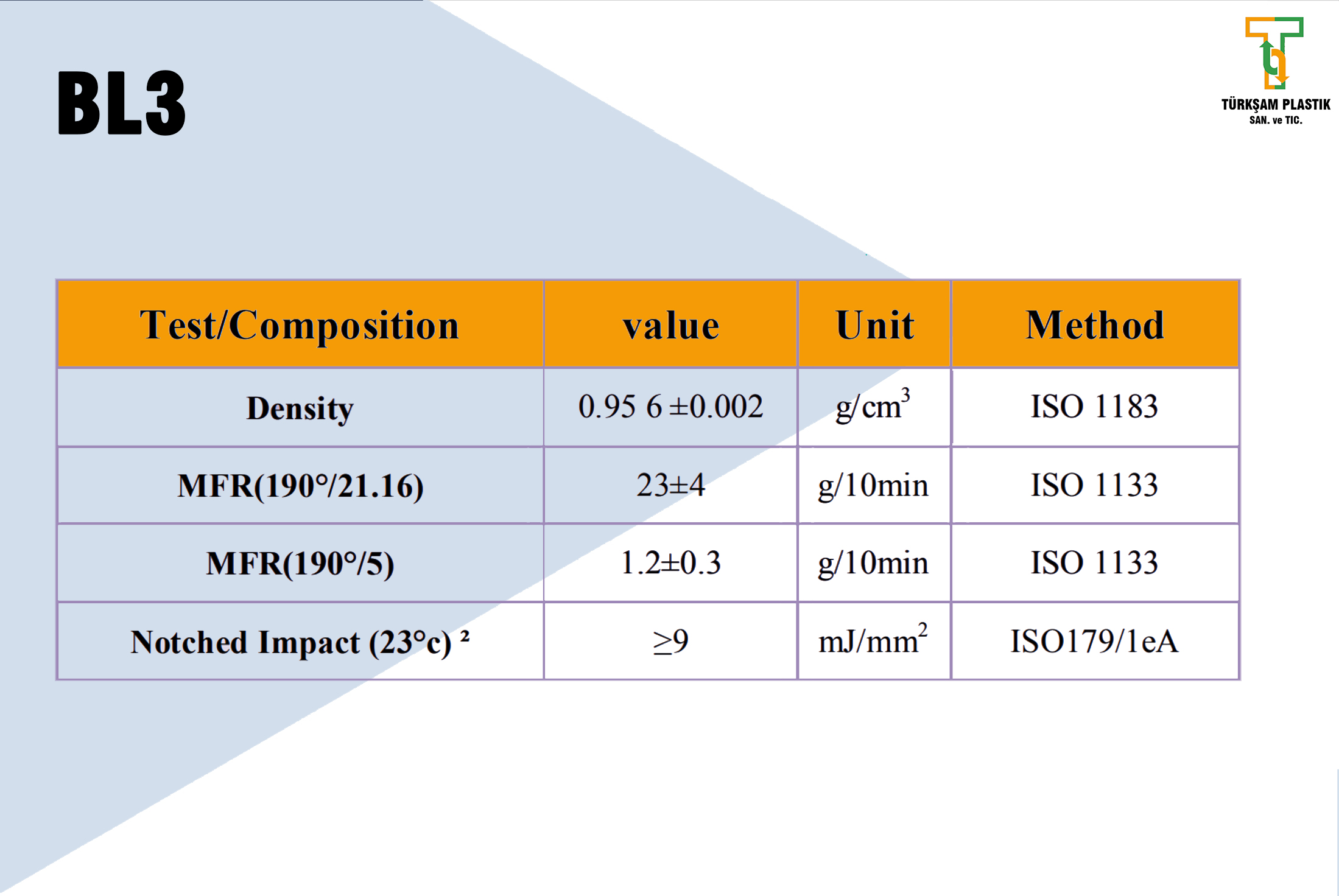

BL3

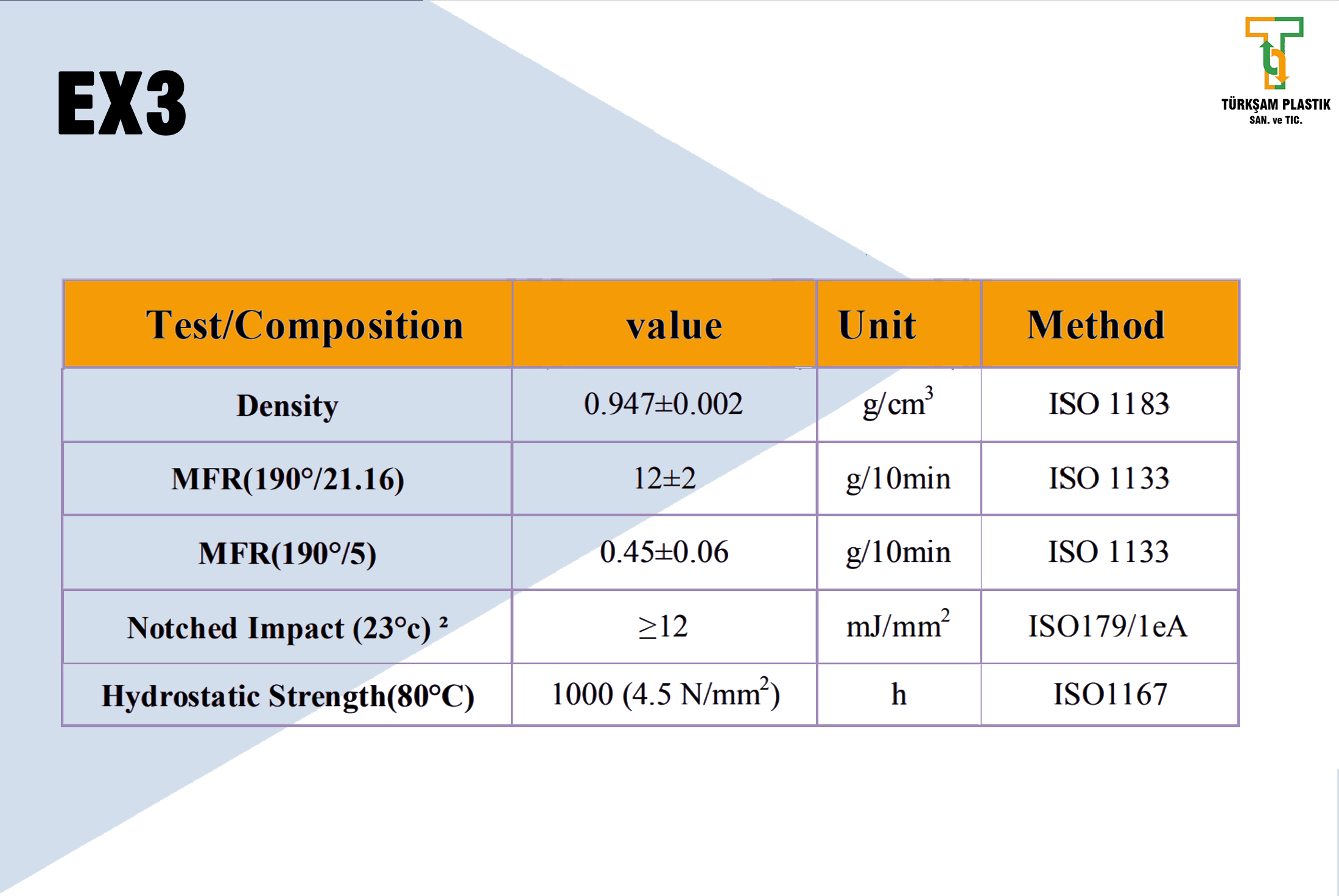

EX3

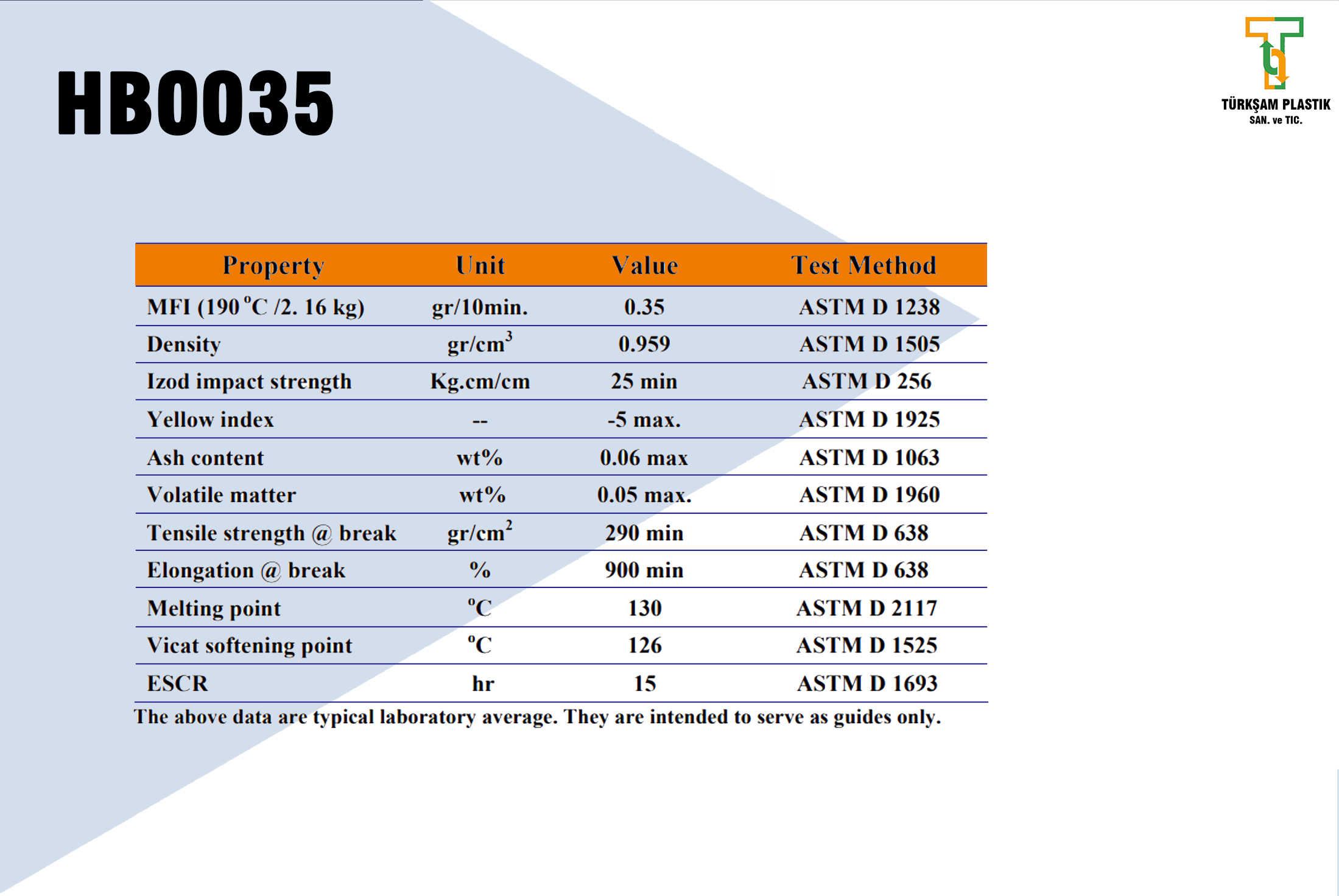

HB0035

.

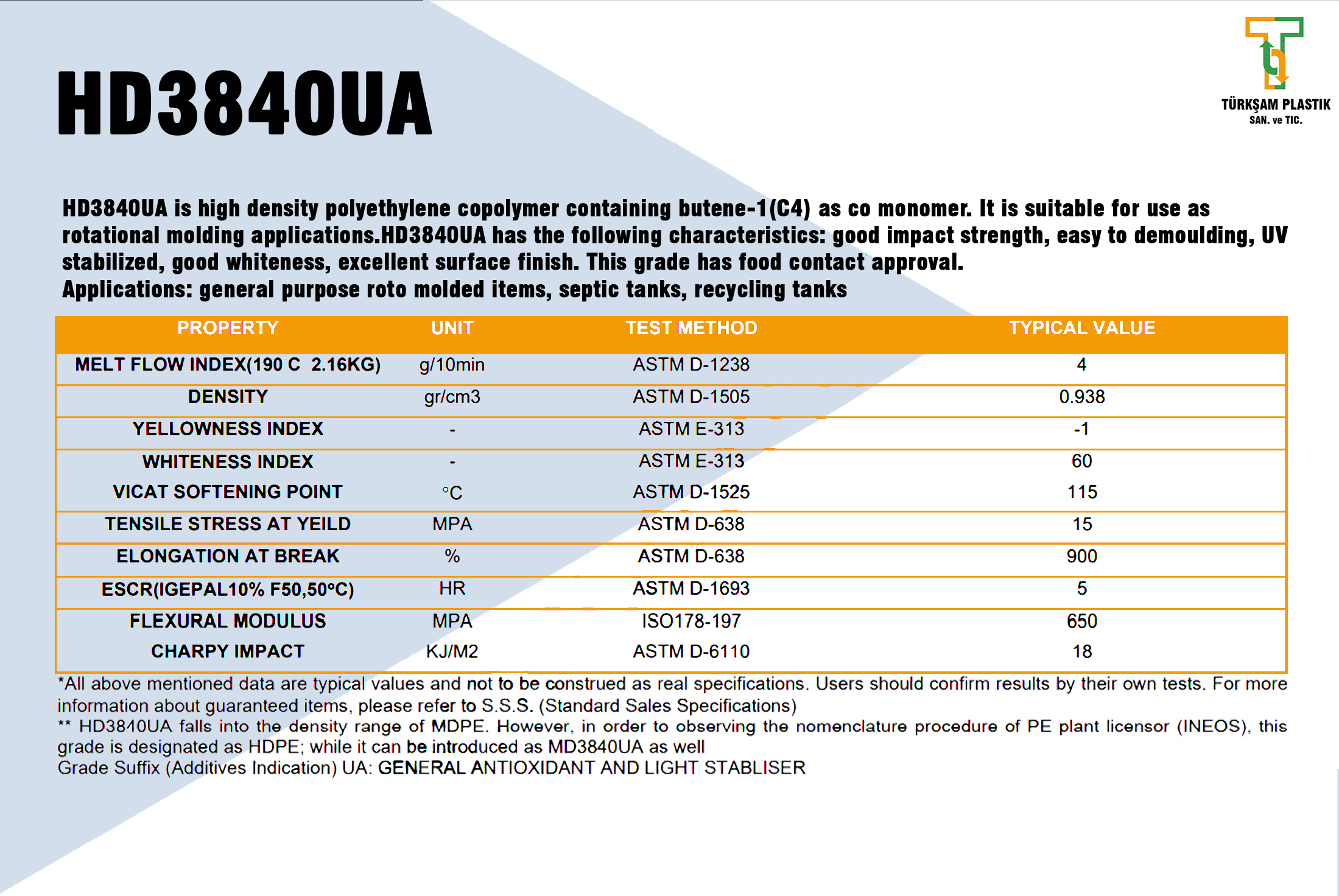

HD3840UA

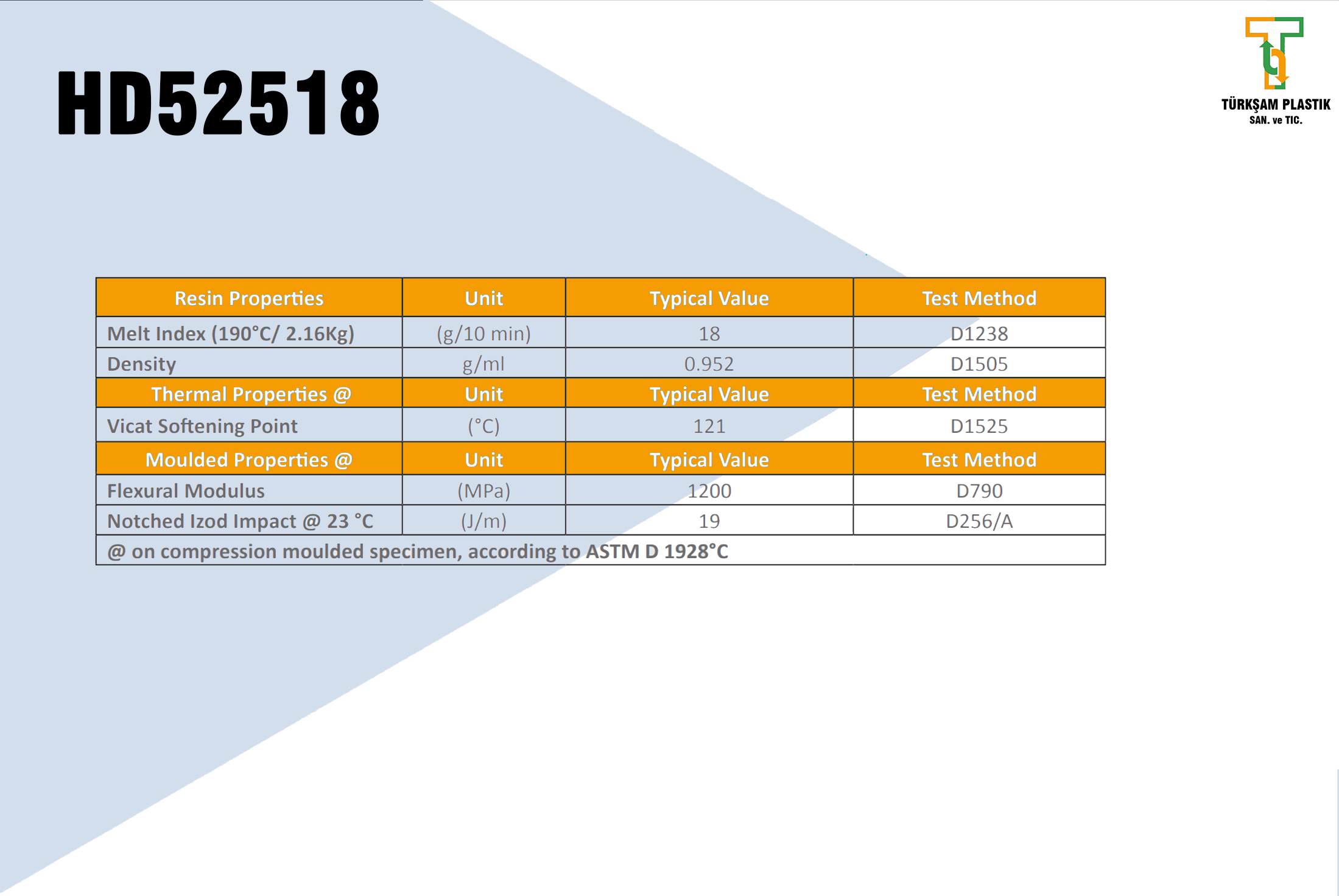

HD 52518

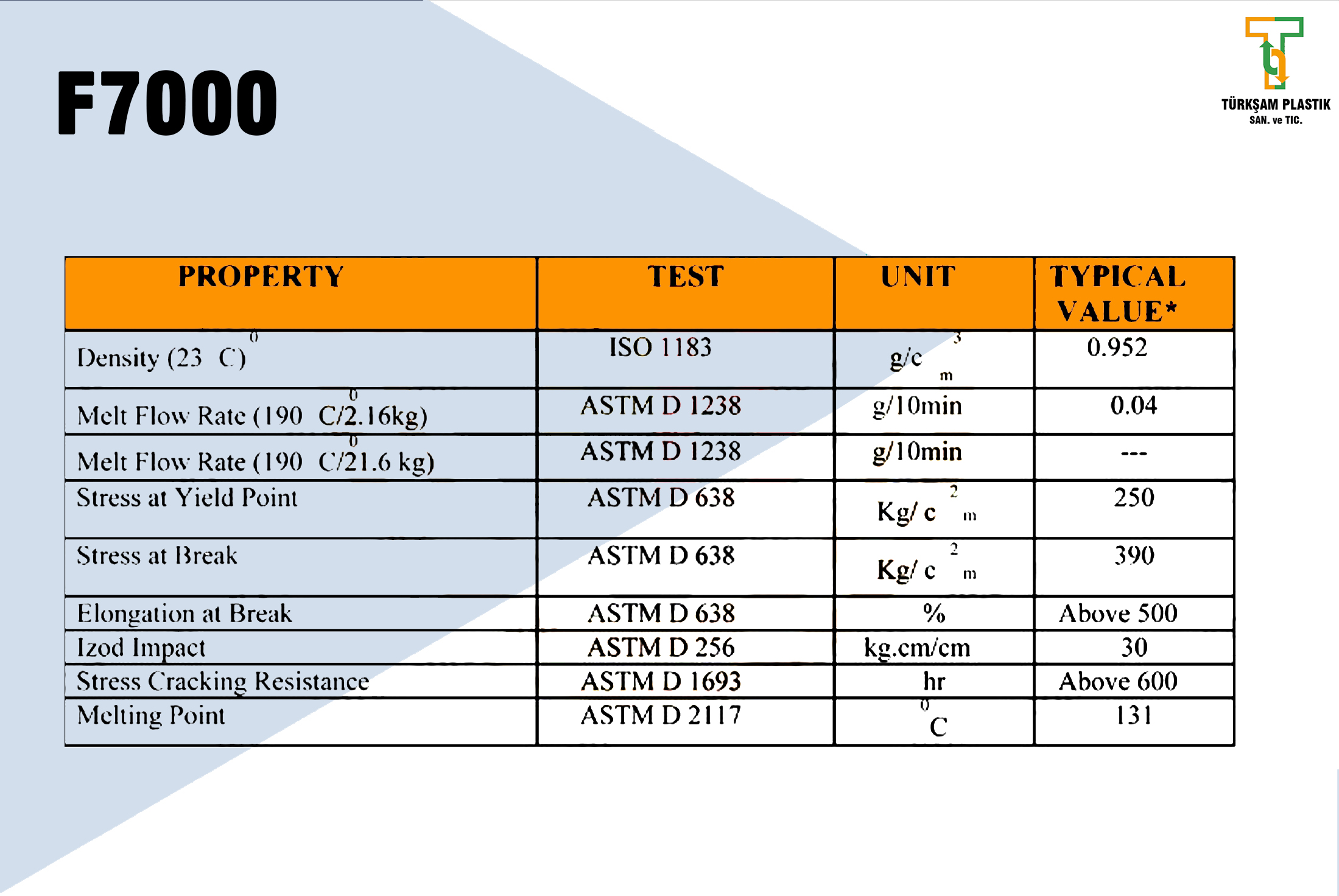

HDPE 7000F

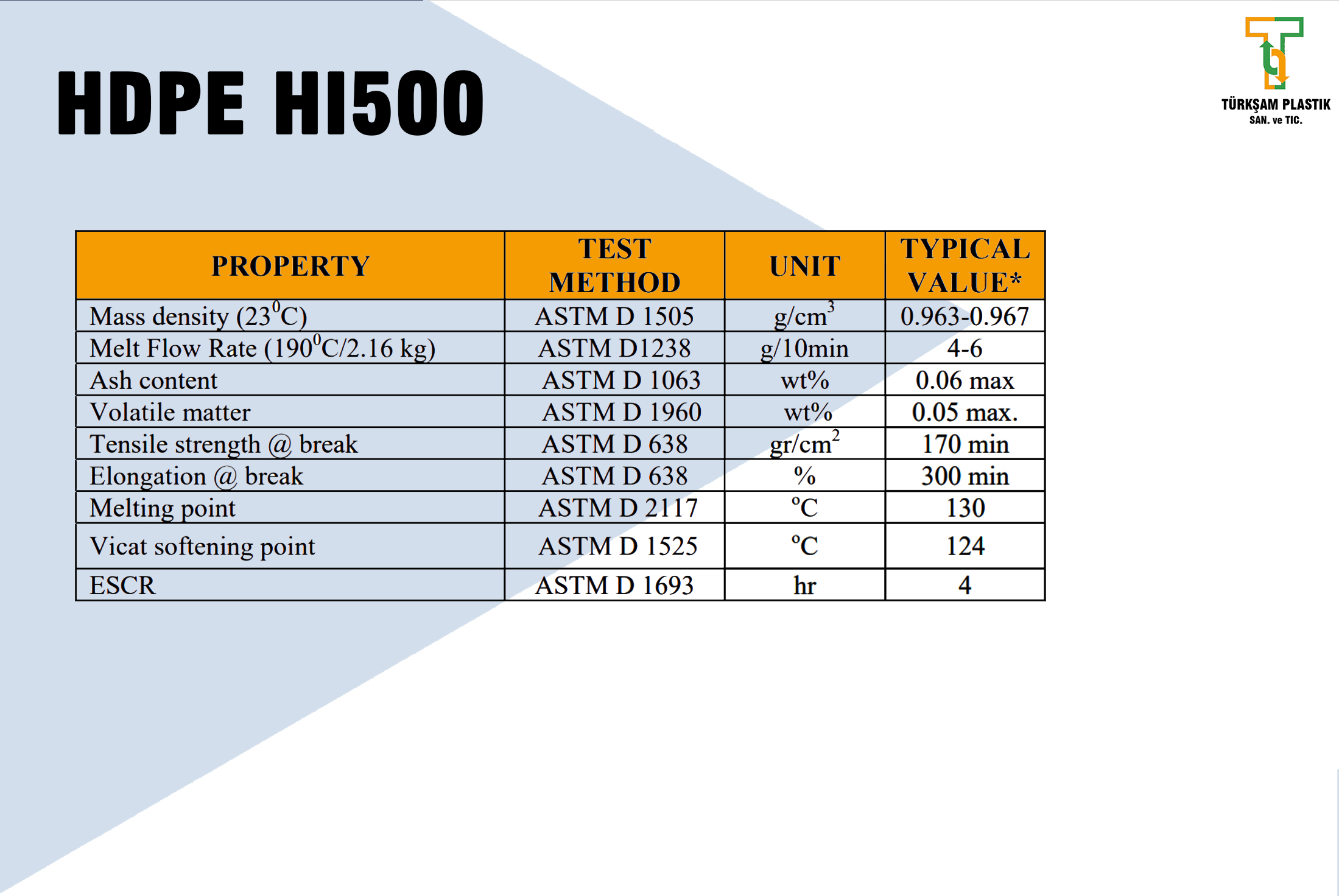

HDPE HI500

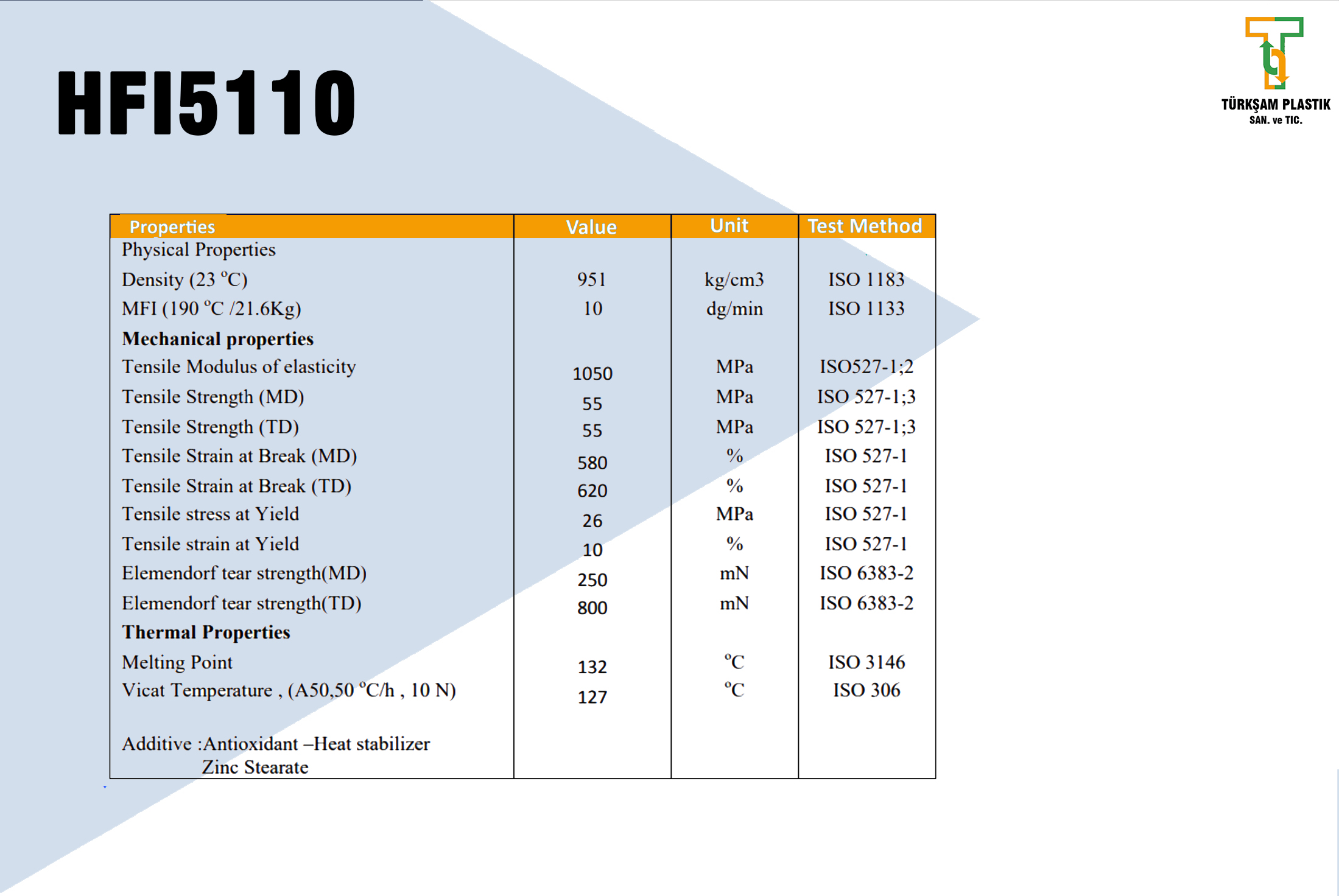

HFI 5110

LLDPE

Linear low-density polyethylene (LLDPE) is a substantially linear polymer (polyethylene), with significant numbers of short branches, commonly made by copolymerization of ethylene with longer-chain olefins. Linear low-density polyethylene differs structurally from conventional low-density polyethylene (LDPE) because of the absence of long chain branching. The linearity of LLDPE results from the different manufacturing processes of LLDPE and LDPE. In general, LLDPE is produced at lower temperatures and pressures by copolymerization of ethylene and such higher alpha-olefins as butene, hexane, or octane. The copolymerization process produces a LLDPE polymer that has a narrower molecular weight distribution than conventional LDPE and in combination with the linear structure, significantly different rheological properties.

LLDPE has penetrated almost all traditional markets for polyethylene; it is used for plastic bags and sheets (where it allows using lower thickness than comparable LDPE), plastic wrap, stretch wrap, pouches, toys, covers, lids, pipes, buckets and containers, covering of cables, geomembranes and mainly flexible tubing

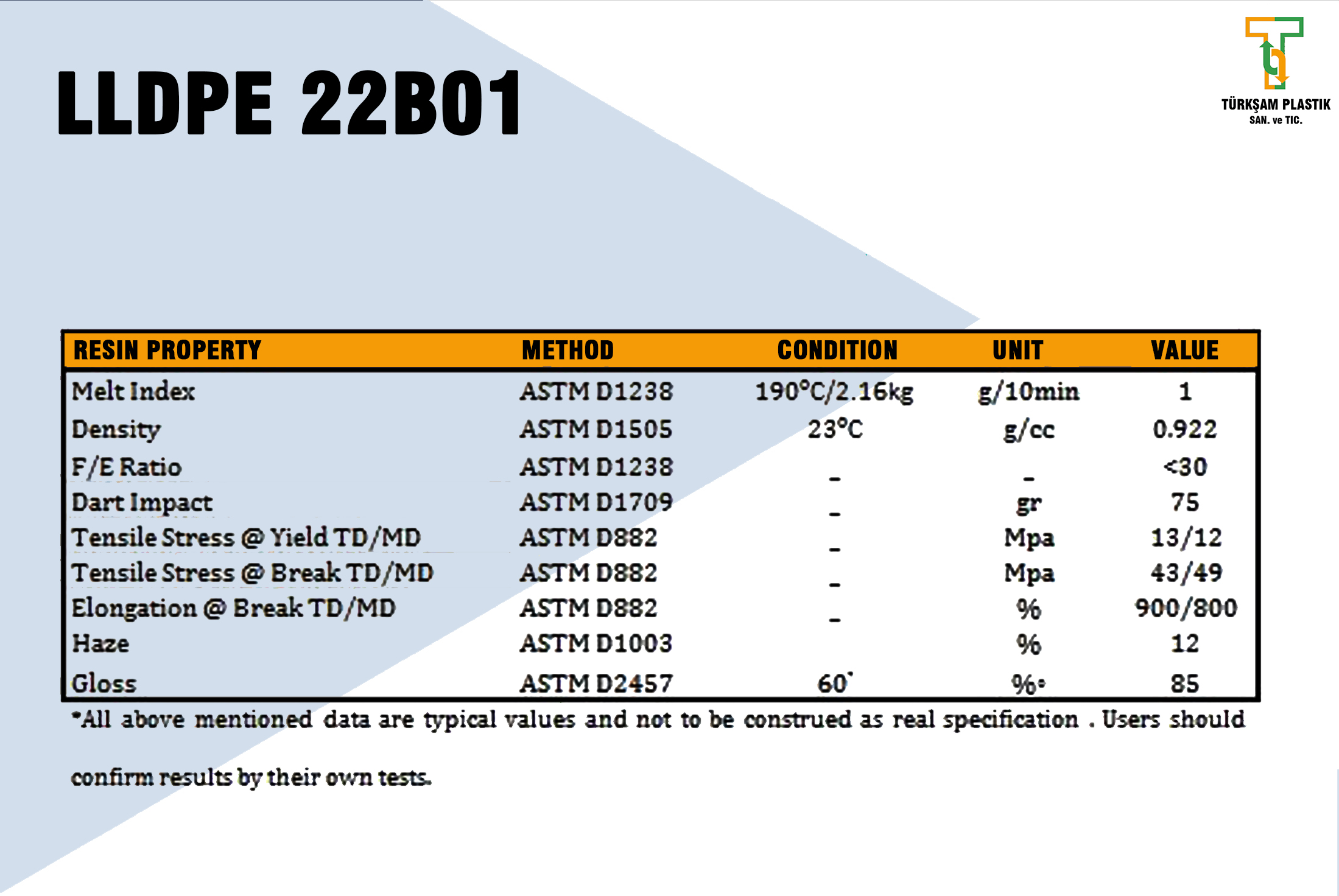

22B01

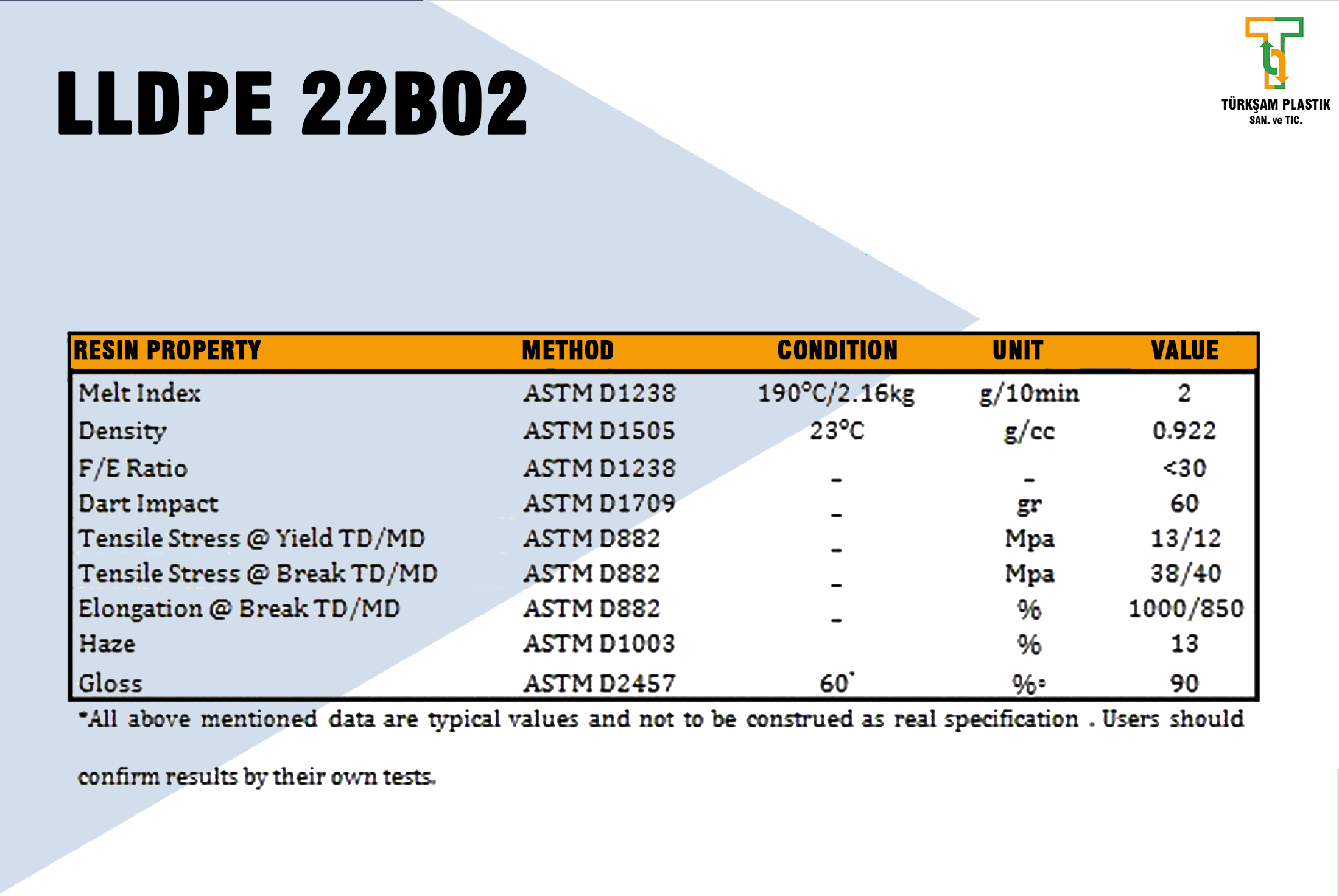

22B02

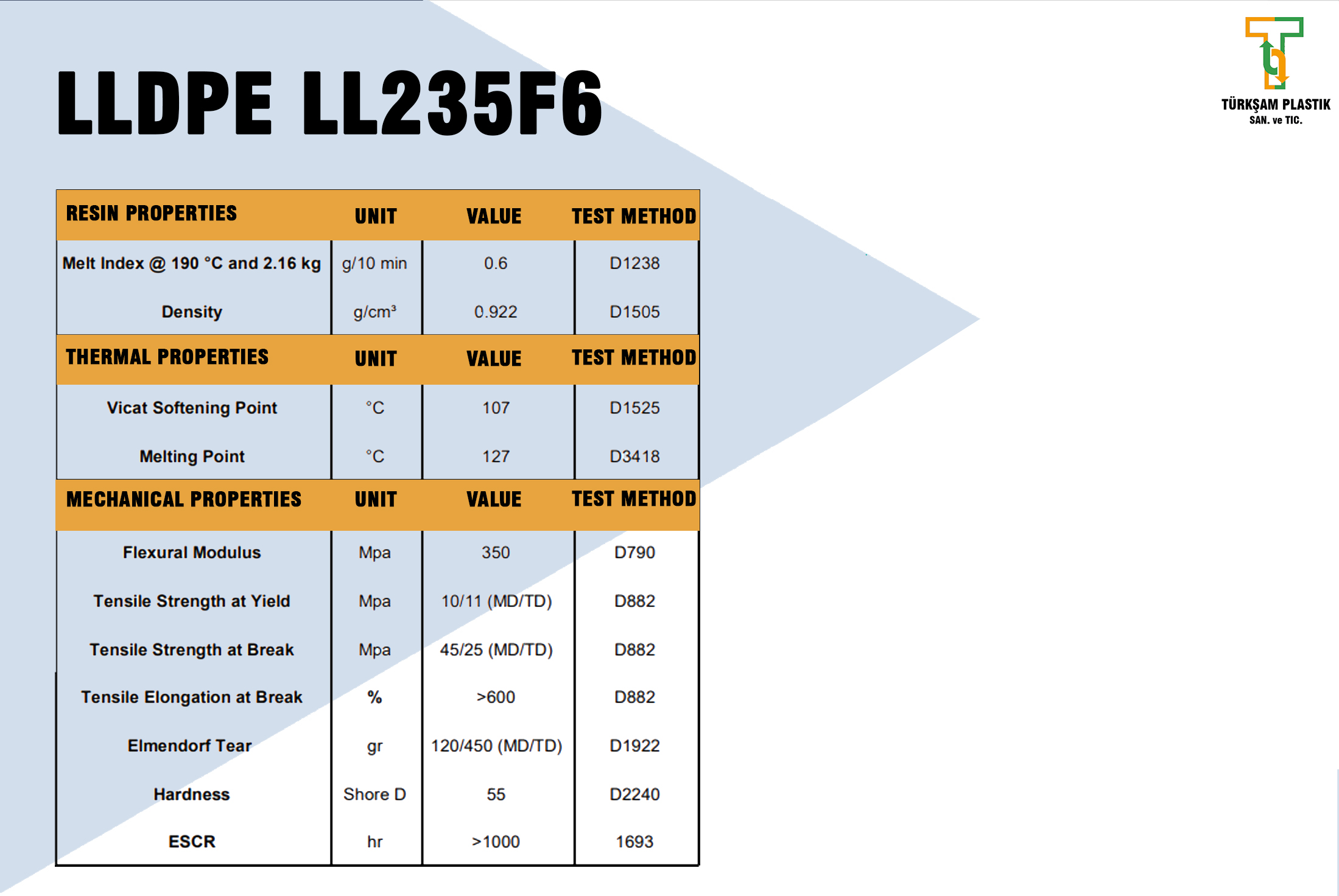

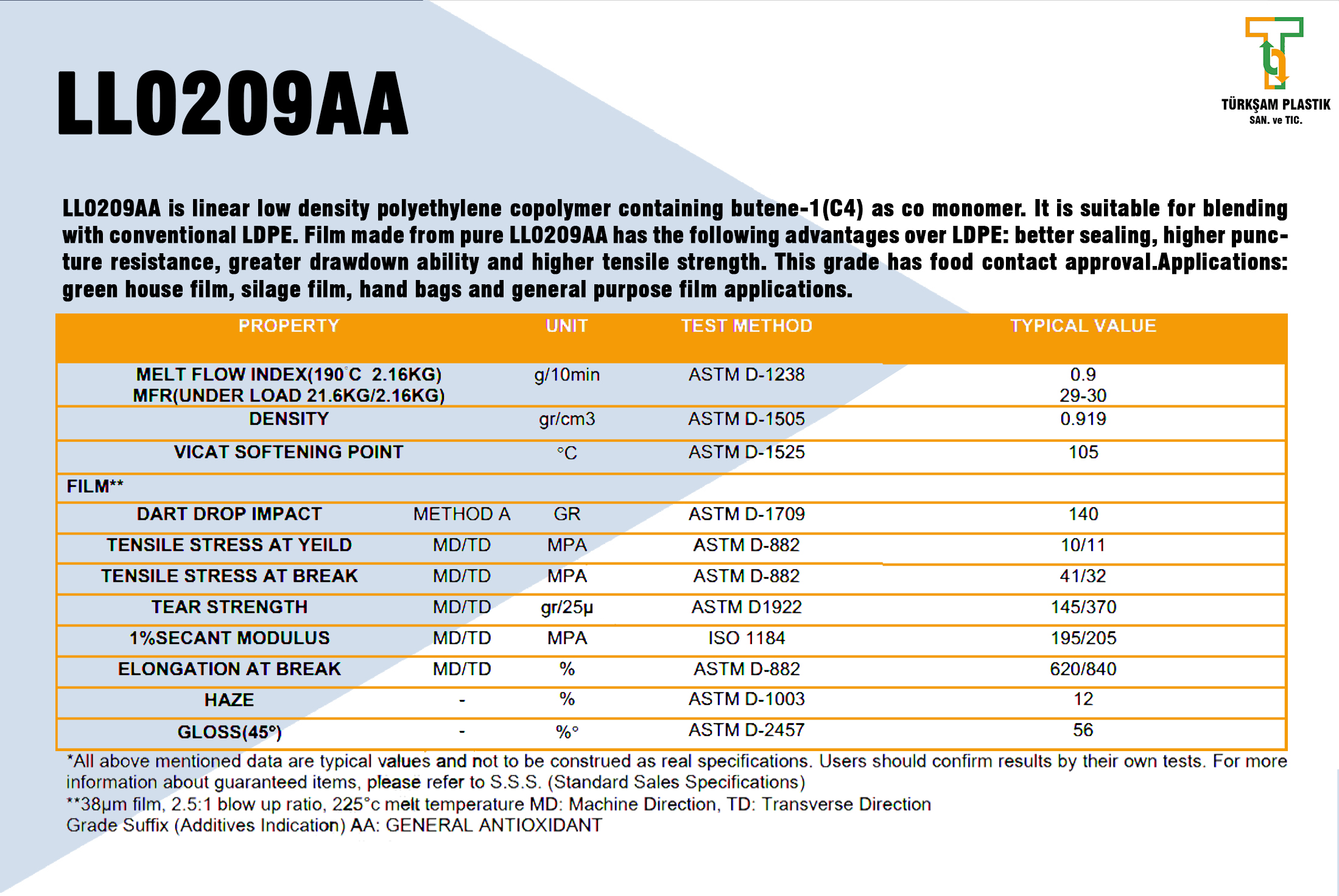

LL 0209AA